Leave Your Message

The textile manufacturing industry is undergoing a significant transformation,

largely driven by advancements in technology and a growing demand for sustainable practices.

Central to this change is the introduction of Automatic Lyocell Equipment, which revolutionizes how lyocell fiber is produced from natural materials.

This cutting-edge equipment not only streamlines the manufacturing process but also enhances efficiency and reduces environmental impact,

aligning with the industry's shift towards more eco-friendly solutions.

By automating intricate production stages, Automatic Lyocell Equipment minimizes human error and labor costs, while maintaining high-quality standards.

As textile manufacturers seek to adopt greener practices and cater to the evolving demands of consumers,

an understanding of Automatic Lyocell Equipment becomes essential for grasping its role in the future of textile production and sustainability.

The textile manufacturing industry is undergoing a significant transformation,

largely driven by advancements in technology and a growing demand for sustainable practices.

Central to this change is the introduction of Automatic Lyocell Equipment, which revolutionizes how lyocell fiber is produced from natural materials.

This cutting-edge equipment not only streamlines the manufacturing process but also enhances efficiency and reduces environmental impact,

aligning with the industry's shift towards more eco-friendly solutions.

By automating intricate production stages, Automatic Lyocell Equipment minimizes human error and labor costs, while maintaining high-quality standards.

As textile manufacturers seek to adopt greener practices and cater to the evolving demands of consumers,

an understanding of Automatic Lyocell Equipment becomes essential for grasping its role in the future of textile production and sustainability.

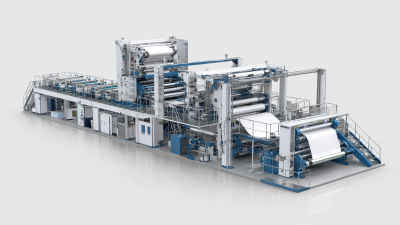

Automatic Lyocell equipment represents a significant innovation in textile manufacturing, specifically designed to streamline the production process of Lyocell fibers. These fibers, derived from sustainably sourced wood pulp, undergo a closed-loop production process where the solvents used are recycled, minimizing environmental impact. The functionality of this equipment lies in its ability to automate several stages of production, including the dissolution of cellulose, fiber spinning, and washing. This automation not only enhances efficiency but also ensures consistent quality, vital for meeting the demands of the textile market.

In addition to enhancing efficiency, Automatic Lyocell equipment contributes to sustainability in textile manufacturing. By reducing the need for manual intervention, it lowers labor costs and minimizes human error, resulting in higher quality fibers with better uniformity. Moreover, the closed-loop process enabled by this equipment ensures that chemical waste is significantly reduced, reinforcing the industry's shift towards more eco-friendly practices. As the demand for sustainable textiles rises, the role of automatic Lyocell equipment is becoming increasingly crucial in transforming the landscape of the textile sector.

The textile industry is rapidly evolving, and Automatic Lyocell Equipment is taking center stage in this transformation. Unlike traditional methods, which often involve labor-intensive processes and significant water usage, Automatic Lyocell systems streamline production, resulting in a more efficient and eco-friendly textile manufacturing process. According to a report by Research and Markets, the global Lyocell fiber market is expected to reach $2 billion by 2025, highlighting the growing demand for sustainable textiles, further driven by advancements in automated technology.

One of the key advantages of Automatic Lyocell Equipment is its ability to reduce water consumption by up to 90% compared to conventional techniques. This is particularly crucial as the textile industry faces increasing scrutiny over its environmental impact. Furthermore, automation minimizes human error and increases output consistency, leading to higher product quality. A study from the European Commission indicates that automated manufacturing processes can increase production efficiency by as much as 25%, underscoring the economic benefits of implementing such technology.

Tips: When considering a shift to Automatic Lyocell Equipment, it’s critical to evaluate the initial investment against long-term savings in operational costs. Also, ensure that your team is trained to use new machinery effectively to maximize the benefits of automation. Emphasizing sustainability will not only improve your brand’s value but will also align with consumer preferences for eco-friendly products.

The adoption of automatic Lyocell technology is reshaping the textile industry, offers numerous advantages, and presents significant trends worth noting. As manufacturers seek sustainable alternatives to conventional textile processes, automatic Lyocell equipment is gaining traction for its ability to simplify production while minimizing environmental impact. This technology not only reduces the energy and water consumption associated with traditional rayon production but also enhances the quality of the final product, making it a preferred choice for eco-conscious brands.

Tips for manufacturers considering the shift to automatic Lyocell technology include investing in training for staff to understand the new equipment and its benefits fully. Understanding the nuances of Lyocell fibers—such as their biodegradability and moisture-wicking properties—can also help in marketing and communicating to consumers about sustainability. Moreover, keeping an eye on market trends and collaborating with technology providers can ensure a smoother transition and greater acceptance of this innovative approach within the supply chain.

As the demand for sustainable textiles grows, the adoption rates of automatic Lyocell technology are expected to rise significantly. Companies that embrace these advancements can not only improve their operational efficiencies but also position themselves as leaders in the push toward sustainability in the fashion sector. With a commitment to integrating these technologies, the textile industry can drive forward a more responsible and eco-friendly future.

Automatic Lyocell equipment represents a significant leap forward in textile manufacturing, particularly in terms of sustainability. This innovative technology streamlines the production process, reducing the consumption of natural resources and minimizing waste. By employing closed-loop systems, automatic Lyocell machinery recycles water and solvents used in the production of lyocell fibers, significantly lowering the environmental footprint compared to traditional textile manufacturing practices.

Moreover, the automatic nature of this equipment enhances efficiency and consistency in production, leading to fewer errors and less product rejection. This not only optimizes resource utilization but also ensures that high-quality fibers are produced with maximum efficacy. As consumers increasingly demand eco-friendly textiles, the integration of automatic Lyocell technology positions manufacturers to meet these expectations, thereby fostering a more sustainable and responsible textile industry.

The implementation of Automatic Lyocell Equipment in textile production promises significant cost savings and efficiency improvements, making it an attractive option for manufacturers. By automating processes, companies can reduce labor costs and minimize human error, leading to higher quality products and increased output. Additionally, the use of lyocell, derived from sustainable sources like wood pulp, aligns with the growing demand for eco-friendly textiles, which can enhance brand reputation and meet consumer expectations for sustainability.

A cost-benefit analysis reveals further advantages. While initial investment costs for automatic equipment may be high, the long-term savings from reduced waste and energy consumption as well as the ability to scale production effectively often outweigh these expenses. Companies can also benefit from advancements in textile recycling technologies, thereby diversifying their product lines and tapping into emerging markets. In light of the industry's shift towards sustainable practices, integrating Automatic Lyocell Equipment could position manufacturers favorably in a competitive landscape that increasingly values environmental responsibility.