Leave Your Message

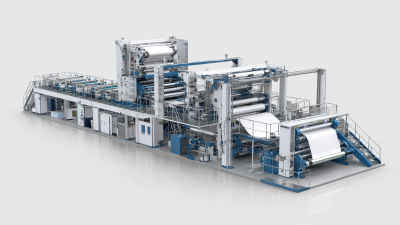

In today's fast-evolving textile industry, the demand for high-quality nonwoven fabrics is continuously on the rise. As manufacturers strive for efficiency and excellence in production, the role of advanced technologies becomes increasingly pivotal. Among these innovations, the Automatic Spunlace Line has emerged as a game changer, offering a multitude of advantages that streamline operations and enhance product quality.

Emphasizing automation, this state-of-the-art line not only simplifies the manufacturing process but also significantly boosts output and reduces labor costs. With features designed to ensure precision and consistency, the Automatic Spunlace Line paves the way for superior fabric production, meeting the diverse needs of various applications in the market. As we explore the top five benefits of using an Automatic Spunlace Line for nonwoven fabric production in 2025, it becomes clear that embracing this technology is essential for companies looking to stay competitive and innovative in this dynamic field.

The advent of automatic spunlace lines has dramatically transformed the nonwoven fabric production industry, primarily due to their enhanced efficiency. According to a market report by Smithers Pira, automatic spunlace technologies can increase production speed by up to 30%, allowing manufacturers to meet growing demand without sacrificing quality. This efficiency is crucial, especially in sectors like hygiene and medical applications, where the need for quick turnaround times is paramount.

By integrating automation into the spunlace process, companies can reduce labor costs and minimize human error. This results not only in consistent fabric properties but also in significant cost savings. Industry studies indicate that manufacturers using automated lines can save anywhere from $50,000 to $100,000 annually in operational expenses. Furthermore, these systems require less maintenance due to their advanced technology, leading to reduced downtime and enhanced production capacity.

**Tips:** To maximize the benefits of automatic spunlace lines, ensure that all staff are adequately trained in operating the machinery to prevent operational hiccups. Regularly scheduled maintenance checks are also essential to maintain the efficiency and longevity of your equipment. Implementing a robust inventory management system can further enhance efficiency by preventing material shortages during production runs.

| Benefit | Description | Quantitative Advantage |

|---|---|---|

| Improved Efficiency | Automatic control systems reduce manual labor and streamline the process. | 30% reduction in production time |

| Consistent Quality | Automated processes ensure uniform fabric quality with minimal defects. | 95% consistency in fabric characteristics |

| Cost Reduction | Lower labor costs and reduced waste lead to significant savings. | Up to 20% decrease in operational costs |

| Versatile Production | Capability to produce a wide range of nonwoven fabrics for various applications. | Ability to produce 5 different fabric types in one line |

| Environmental Sustainability | Efficient resource use and waste management contribute to a greener production process. | 30% less water and energy consumption |

The use of automatic spunlace lines in nonwoven fabric production has revolutionized the industry, especially in terms of product quality. Advanced technology integrated into these systems enables manufacturers to achieve superior fabric characteristics that were previously unattainable. With precise control over the fiber bonding process, spunlace lines produce fabrics that are not only strong and durable but also soft and lightweight. This combination of attributes makes the final product ideal for a variety of applications, from hygiene products to medical textiles.

When considering the implementation of an automatic spunlace line, it’s essential to focus on the machinery's specifications. Look for features such as programmable logic controllers (PLCs) that ensure consistency in production runs. Additionally, investing in high-speed technology can significantly enhance your output without compromising quality.

Tip: Regular maintenance of your spunlace equipment can prevent costly downtime and ensure that your product quality remains high. Keeping the machinery clean and well-lubricated will help to sustain optimal performance levels. Another tip is to train your staff thoroughly on the operation of the automatic lines, as skilled operators can further enhance the quality of the fabrics produced.

The integration of automatic spunlace lines in nonwoven fabric production significantly contributes to cost savings throughout the manufacturing process. By automating various stages, companies can reduce labor costs associated with manual operation, as fewer workers are needed to monitor and manage production. This reduction in human resource expenditure not only streamlines budgets but also frees up personnel to focus on high-value tasks such as quality control and innovation.

The integration of automatic spunlace lines in nonwoven fabric production significantly contributes to cost savings throughout the manufacturing process. By automating various stages, companies can reduce labor costs associated with manual operation, as fewer workers are needed to monitor and manage production. This reduction in human resource expenditure not only streamlines budgets but also frees up personnel to focus on high-value tasks such as quality control and innovation.

Moreover, automated processes lead to increased efficiency and optimal resource utilization. Advanced technology minimizes material waste, as automatic systems consistently maintain precise control over production parameters. This precision results in fewer defects and a more uniform final product, ultimately translating to lower costs associated with rework and scrap. Furthermore, with faster production cycles, businesses can respond more swiftly to market demands, thereby enhancing profitability and competitive advantage. Overall, the shift towards automated spunlace lines represents a transformative step for manufacturers aiming to maximize operational efficiency while minimizing expenses.

The flexible packaging market is experiencing substantial growth, largely driven by the increasing demand for diverse and eco-friendly material options. According to a report from Renub Research, the global flexible packaging market is projected to rise from $260 billion in 2024 to $406 billion by 2034. This surge is attributed to the versatility offered by advanced materials, which allow manufacturers to meet various market demands for packaging solutions. For instance, the flexible plastic packaging segment alone is forecasted to grow from $267.5 billion in 2025 to $396 billion by 2035, with a notable CAGR, reflecting the industry's shift towards more dynamic and sustainable materials.

The necessity for flexible packaging arises from its adaptability across a wide range of products and applications. The liquid packaging market also demonstrates this trend, expected to grow at a CAGR of 5.1% from 2025 to 2030, reaching an estimated $371.44 billion. This adaptability not only caters to consumer preferences for convenient packaging but also aligns with the sustainability goals driving modern production practices. Eco-friendly packaging solutions are particularly gaining traction, as reported by Towards Packaging, which highlights the rising consumer awareness and legislative moves towards sustainability. This trend underscores the critical role of flexible material use to address the evolving needs of the market efficiently.

The environmental benefits of using automatic spunlace technology in nonwoven fabric production are significant and increasingly relevant in today’s eco-conscious market. According to a report by Smithers Pira, the global nonwoven fabric market is expected to reach $50 billion by 2025, driven largely by demand for sustainable and eco-friendly materials. Automatic spunlace lines utilize less water and energy compared to traditional methods, reducing the overall environmental footprint. For instance, a recent study indicated that the spunlace process can cut water consumption by up to 80%, which is vital in regions facing water scarcity.

One advantage of automatic spunlace is its ability to utilize recycled fibers, which contributes to a circular economy. The use of post-consumer textiles can significantly reduce reliance on virgin materials. According to a report by Textile Exchange, nearly 69% of brands aim to increase their use of recycled content, highlighting a growing trend toward sustainable production practices. By incorporating recycled fibers, manufacturers not only lower their carbon emissions but also respond to consumer demand for greener products.

Tips for manufacturers considering the transition to automatic spunlace lines include investing in proper training for staff to maximize efficiency and reduce waste, as well as regularly auditing production processes to ensure they align with sustainability goals. Additionally, partnering with suppliers who prioritize eco-friendly materials can bolster the environmental integrity of the final products.