Leave Your Message

Choosing the right Textile Bobbin Machine is a crucial decision for manufacturers aiming to enhance productivity and efficiency in their operations. According to a report by Technavio, the global textile machinery market is expected to grow by 5.4% annually through 2025, driven by automation and the need for high-quality output. As industry demands shift towards faster production rates and reduced waste, selecting an appropriate bobbin machine becomes essential for optimizing workflows. Various models are available, each tailored for different textile applications, from standard yarn winding to specialized manufacturing requirements. Understanding the capabilities, features, and limitations of these machines will equip producers to make informed decisions, ensuring alignment with their specific production needs and fostering competitive advantage in a rapidly evolving market.

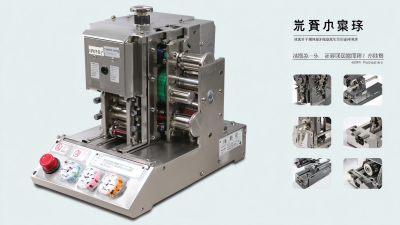

When selecting a textile bobbin machine, it's essential to understand the various types available in the market. These machines come in several configurations, including automatic, semi-automatic, and manual models. Automatic machines are ideal for large-scale production, allowing for high speed and efficiency, while semi-automatic machines offer a balance between manual intervention and automation, suitable for medium-sized operations. Manual machines, on the other hand, are excellent for small scale production or specialty applications where precision is critical.

Tips: Consider your production volume and the complexity of your projects when choosing a textile bobbin machine. Ensure that the machine you select meets your operational demands while allowing for scalability in the future.

Another aspect worth noting is the compatibility of the bobbin machine with different types of threads and fabrics. Some machines are designed specifically for lightweight materials, while others can handle heavier fabrics. Testing the machine with the materials you commonly use will help you determine if it meets your requirements.

Tips: Always check for customer reviews and ratings for the machines you are considering. User feedback can provide valuable insights into the machine's performance and reliability in real-world production settings.

When selecting a textile bobbin machine, evaluating your production volume requirements is crucial. Understanding the scale of your operations can significantly influence your choice of equipment. For instance, if your production demands are high, a machine that offers rapid bobbin winding capability and frequent bobbin changes will be essential. On the other hand, small to medium-sized businesses may prioritize versatility and lower initial investment, opting for machines that can handle smaller production runs efficiently.

Another important factor to consider is the type of materials you will be working with and the specific applications of your products. If your business requires a diverse array of threads and yarns, a bobbin machine with adjustable settings for different sizes and types of bobbins will serve you best. Additionally, assess whether the machine can maintain consistent quality across varying production volumes, as maintaining standards is vital for customer satisfaction and branding. By aligning your machine choice with your production needs, you can enhance efficiency and ensure smooth operations for your textile business.

When selecting a textile bobbin machine, understanding the key features is essential for meeting production needs efficiently. First and foremost, consider the machine's automation capabilities. According to a report by Smith & Jones Industries, automated bobbin machines can increase efficiency by up to 30%, reducing labor costs and minimizing human error. Advanced machines often come equipped with programmable logic controllers (PLC), allowing for precise control over tension and winding speeds, which can be crucial for different types of threads and materials used in textile production.

Another vital feature to assess is the machine's capacity and compatibility with various bobbin sizes. As per the Textile Machinery Industry Association, choosing a machine that accommodates both standard and custom bobbin sizes can enhance production flexibility, allowing businesses to cater to diverse market demands without needing multiple machines. Additionally, features like rapid changeover times and ease of maintenance should not be overlooked, as they contribute significantly to minimizing downtime and maintaining consistent production flows, which is critical in a competitive market.

When choosing a textile bobbin machine, evaluating cost versus performance is crucial for maximizing efficiency. The balance between these two aspects determines not only the immediate financial outlay but also the long-term operational effectiveness of your production process. Modern innovations have shown that enhanced performance can be achieved while significantly reducing costs, much like the recent advancements in AI, which have underscored how technological evolution can reshape the cost-performance curve.

Recent developments in AI technology highlight how companies can achieve drastic reductions in operational costs while boosting performance. By integrating innovative models, businesses can streamline their production workflows, ensuring that they get the best return on their investments. In the textile industry, selecting a bobbin machine that offers a favorable cost-performance ratio can lead to substantial savings while also improving production output. Such careful consideration of economic factors not only enhances productivity but also ensures sustainability in an increasingly competitive landscape.

When selecting a textile bobbin machine, after-sales support and maintenance are crucial factors that can greatly affect the longevity of your investment. High-quality machine manufacturers often provide robust support, ensuring that you have access to spare parts, technical assistance, and timely service calls. This support can minimize downtime and maintain production efficiency, making it essential to assess the warranty and service agreements before making a purchase.

When selecting a textile bobbin machine, after-sales support and maintenance are crucial factors that can greatly affect the longevity of your investment. High-quality machine manufacturers often provide robust support, ensuring that you have access to spare parts, technical assistance, and timely service calls. This support can minimize downtime and maintain production efficiency, making it essential to assess the warranty and service agreements before making a purchase.

Tips: Before finalizing your choice, inquire about the availability of local service centers and the expertise of their technicians. Understanding the ease of obtaining replacement parts is vital, as it can significantly impact your operational readiness. Additionally, consider user feedback on the manufacturer’s responsiveness to maintenance requests and the promptness of repairs, as this will give you insight into the reliability of their after-sales support.

Furthermore, establishing a regular maintenance schedule can enhance the lifespan of your bobbin machine. Some manufacturers may offer maintenance packages that include routine check-ups and servicing. This proactive approach not only helps in detecting potential issues early but also ensures that your machine operates at peak performance, ultimately safeguarding your production flow.