Leave Your Message

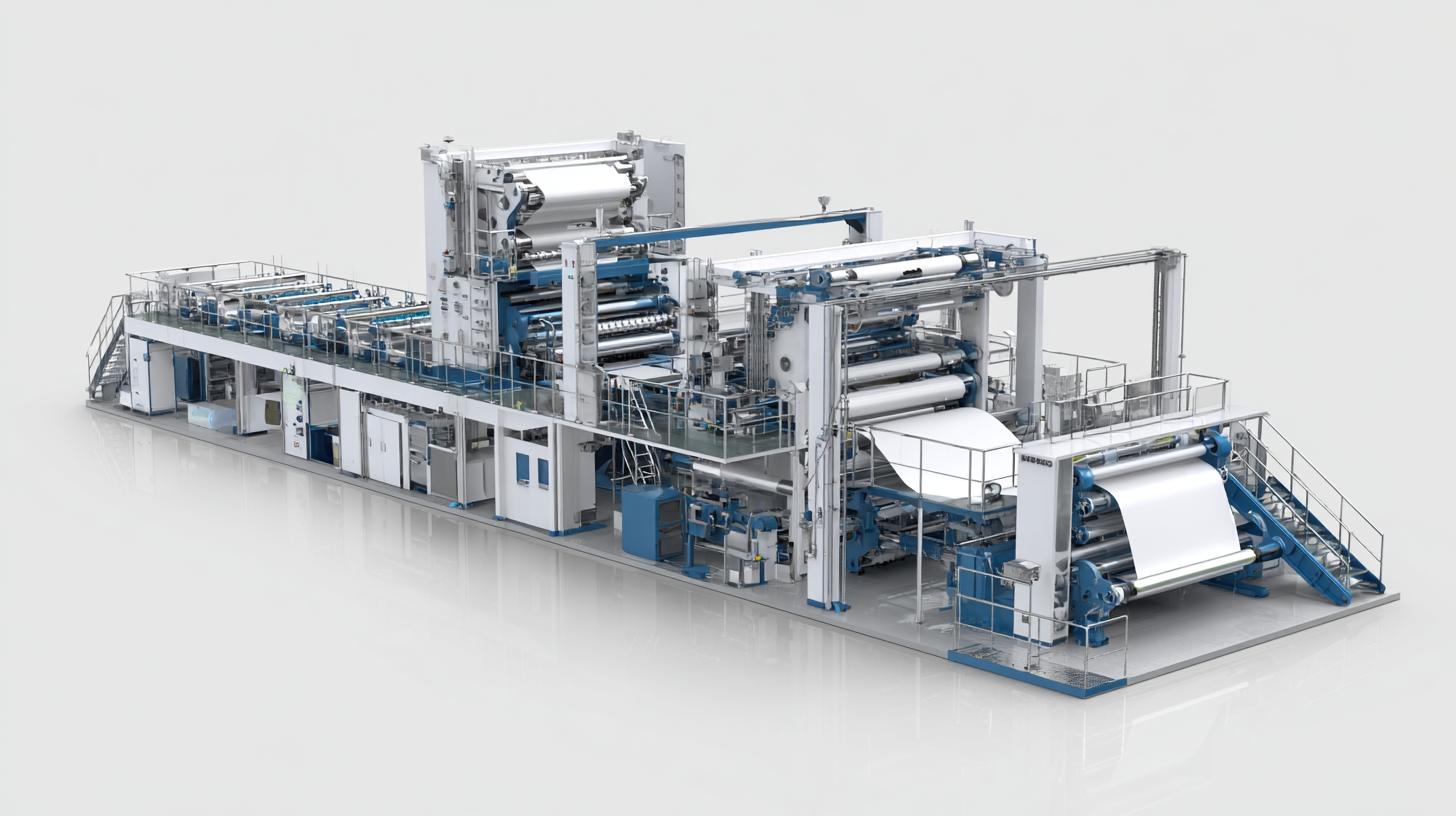

In the rapidly evolving landscape of nonwoven fabric production, the Automatic Spunlace Line stands out as a pivotal innovation, enhancing both efficiency and product quality. As manufacturers strive to meet the surging demand for sustainable and high-performance materials, understanding the various options available in the market becomes crucial. This blog delves into an ultimate comparison of top Automatic Spunlace Lines, focusing on industry performance metrics that impact operational success. By evaluating parameters such as

production speed, material versatility, energy consumption, and maintenance requirements, we aim to provide insightful solutions tailored for businesses looking to optimize their production lines.

Join us as we explore the leading technologies in this sector and identify the key factors that can propel your manufacturing process to new heights.

Join us as we explore the leading technologies in this sector and identify the key factors that can propel your manufacturing process to new heights.

When assessing the performance of automatic spunlace lines, key performance indicators (KPIs) play a crucial role in determining their efficiency and reliability. Among the top metrics, production speed stands out, with industry benchmarks indicating that high-performing lines can achieve speeds of up to 300 meters per minute. This capability significantly enhances operational throughput, allowing manufacturers to meet rising demand without compromising on quality.

Another critical KPI to consider is the raw material utilization rate, which can often exceed 90% in leading spunlace technologies. This efficiency is not only economically beneficial but also aligns with sustainability goals by minimizing waste. Furthermore, downtime rates, ideally maintained below 2%, are essential for ensuring consistent production schedules. Reports suggest that advanced automatic lines with predictive maintenance features can greatly reduce unplanned interruptions, thus maximizing uptime and productivity. By focusing on these performance metrics, manufacturers can make informed decisions when investing in automatic spunlace lines that optimize both operational efficiencies and product quality.

When evaluating the performance of automatic spunlace lines, one must consider several key industry metrics that highlight efficiency, quality, and overall effectiveness. Metrics such as

production output,

downtime rates, and

energy consumption play a crucial role in assessing the lines' capabilities. According to a recent report by

Smith & Co. (2023), top-performing spunlace lines achieve a production efficiency rate of

92%, while the industry average hovers around

85%. This significant difference underscores the importance of choosing the right equipment for maximizing productivity.

Tip: Always monitor your production output against industry standards. Identifying discrepancies can help you pinpoint areas that require improvement or investment in technology.

Further, analyzing downtime is essential. The same Smith & Co. report reveals that leading manufacturers maintain a downtime rate of less than

5%, ensuring streamlined operations. In contrast, companies with older machinery often face downtimes exceeding

15%. This metric not only affects immediate production but also impacts long-term operational costs.

Tip: Implement a routine maintenance schedule to keep equipment running smoothly and reduce unexpected downtimes. Regular checks can enhance both longevity and performance.

In summary, leveraging these industry performance metrics provides valuable insights that can guide your investment decisions and operational strategies regarding automatic spunlace lines.

The automatic spunlace line industry has seen significant advancements, driven by innovations from top brands that are reshaping the landscape of nonwoven fabric production. Key players are investing heavily in cutting-edge technology to enhance efficiency, reduce waste, and improve product quality. Brands like Ahlstrom-Munksjö and Sandler have introduced state-of-the-art machinery that boasts higher throughput rates and energy efficiency, catering to the increasing demand for sustainable manufacturing processes.

Moreover, notable innovations such as real-time monitoring systems and advanced automation are helping manufacturers optimize their production lines. For instance, some brands have integrated AI-driven analytics to predict machine performance and maintenance needs, thus minimizing downtime and maximizing output. These technological strides not only improve production efficiency but also allow for greater customization of spunlace products, meeting diverse market requirements across hygiene, medical, and industrial applications. The race for innovation among these top brands is redefining industry standards and setting a benchmark for future developments in automatic spunlace lines.

| Performance Metrics | Line Speed (m/min) | Production Capacity (Tons/Day) | Energy Efficiency (%) | Technology Used |

|---|---|---|---|---|

| Automatic Spunlace Line A | 150 | 30 | 87 | Eco-Friendly |

| Automatic Spunlace Line B | 175 | 40 | 91 | High-Speed Technology |

| Automatic Spunlace Line C | 160 | 35 | 85 | Compact Design |

| Automatic Spunlace Line D | 180 | 45 | 93 | Intelligent Control System |

| Automatic Spunlace Line E | 170 | 38 | 88 | Robust Engineering |

In the competitive landscape of spunlace production, cost efficiency has emerged as a critical metric for manufacturers aiming to optimize performance. Recent industry reports highlight that the cost of raw materials constitutes approximately 60% of the total production expense, with fibers like viscose and polyester being pivotal. By leveraging bulk purchasing and strategic supplier relationships, companies can significantly reduce input costs, enhancing their overall profitability. According to a 2023 market analysis, manufacturers who implemented cost-efficient sourcing methods saw a reduction in material costs by up to 15%, directly influencing their bottom line.

Moreover, operational efficiencies play a vital role in minimizing production costs. Automated spunlace lines have shown a marked improvement in throughput and waste reduction, with some top-performing lines exhibiting a 30% decrease in energy consumption compared to older models. This shift not only lowers operational costs but also aligns with the growing emphasis on sustainability within the industry. The integration of advanced process control technologies has enabled production facilities to maintain high levels of output while minimizing downtime, further contributing to cost savings. In fact, facilities that invested in automation reported an average increase in operational efficiency by 25%, making a compelling case for modernization in the spunlace sector.

As advancements in automatic spunlace technology continue to evolve, key innovations are reshaping the landscape of textile production. Recent reports indicate that automated systems in spunlace lines can increase production efficiency by up to 25%, driving down costs and minimizing waste. The integration of smart sensor technologies is pivotal, allowing for real-time monitoring and quality control throughout the manufacturing process. This level of precision not only enhances product quality but also supports sustainability initiatives by reducing resource consumption.

As advancements in automatic spunlace technology continue to evolve, key innovations are reshaping the landscape of textile production. Recent reports indicate that automated systems in spunlace lines can increase production efficiency by up to 25%, driving down costs and minimizing waste. The integration of smart sensor technologies is pivotal, allowing for real-time monitoring and quality control throughout the manufacturing process. This level of precision not only enhances product quality but also supports sustainability initiatives by reducing resource consumption.

Tips: When considering upgrades to your automatic spunlace lines, focus on systems that integrate AI and machine learning to optimize operations. These technologies not only predict maintenance needs but also adjust settings for varying material properties, enhancing flexibility in production.

Furthermore, industry studies suggest that the use of advanced robotics in spunlace lines can reduce labor costs significantly while maintaining output quality. Embracing such technologies is no longer a luxury but a necessity for companies aiming to stay competitive in a rapidly changing market.

Tips: Evaluate your current production processes and identify areas where automation could streamline operations. Investing in the latest automation technology will lead to improved profitability and market responsiveness in the long run.