Leave Your Message

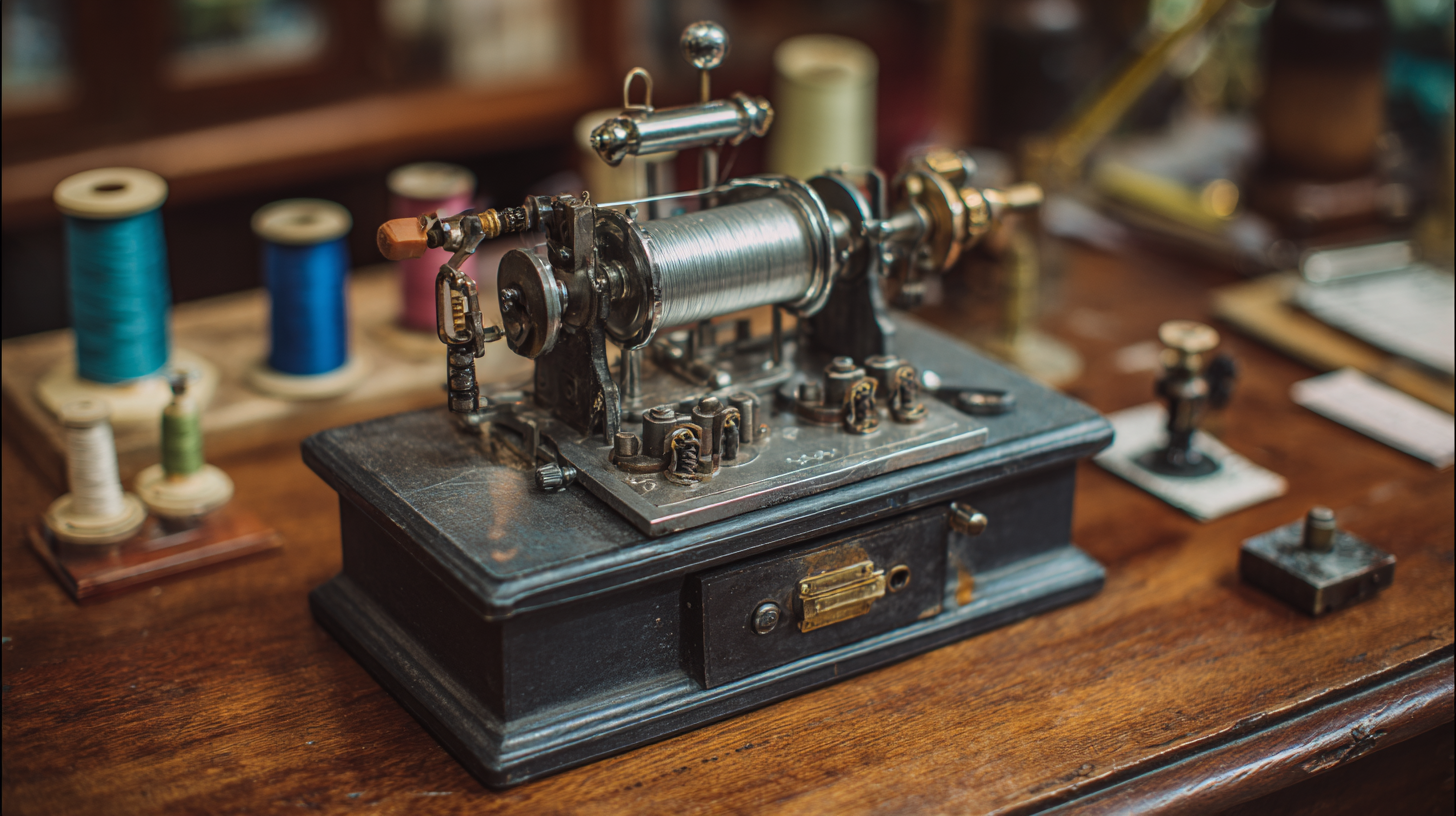

The textile industry is undergoing a significant transformation, driven by advancements in technology and an increasing demand for customizable, high-quality products.

Mini Textile Machines have emerged as a key player in this evolution, providing accessible and efficient solutions for both small-scale and home-based textile production.

According to a report from the Global Textile Machinery Market, the mini textile machine segment is expected to grow by 7% annually, reflecting a surge in interest from emerging entrepreneurs and hobbyists.

These compact machines not only reduce operational costs but also offer versatility in handling a variety of fabrics, making them suitable for a diverse range of applications—from fashion design to home decor.

As more individuals seek to explore textile crafting or start their own businesses, understanding how to efficiently operate a Mini Textile Machine becomes essential for achieving success and maximizing productivity in this vibrant industry.

Mini Textile Machines have emerged as a key player in this evolution, providing accessible and efficient solutions for both small-scale and home-based textile production.

According to a report from the Global Textile Machinery Market, the mini textile machine segment is expected to grow by 7% annually, reflecting a surge in interest from emerging entrepreneurs and hobbyists.

These compact machines not only reduce operational costs but also offer versatility in handling a variety of fabrics, making them suitable for a diverse range of applications—from fashion design to home decor.

As more individuals seek to explore textile crafting or start their own businesses, understanding how to efficiently operate a Mini Textile Machine becomes essential for achieving success and maximizing productivity in this vibrant industry.

Operating a mini textile machine efficiently requires a strong foundation of essential tools and equipment. Firstly, having a reliable sewing machine with various stitch options can enhance your crafting experience. Choose one that fits your needs, whether for simple repairs or intricate designs. Additionally, a cutting mat and rotary cutter are invaluable for precise fabric cutting, ensuring you achieve clean edges and accurate shapes in your projects.

Operating a mini textile machine efficiently requires a strong foundation of essential tools and equipment. Firstly, having a reliable sewing machine with various stitch options can enhance your crafting experience. Choose one that fits your needs, whether for simple repairs or intricate designs. Additionally, a cutting mat and rotary cutter are invaluable for precise fabric cutting, ensuring you achieve clean edges and accurate shapes in your projects.

Another important tool is a set of sewing needles tailored for different fabrics. This will help you easily maneuver through various materials, ensuring a smoother sewing process. Fabric scissors designed for your specific textile type can also make a significant difference in the quality of your cuts. Don't forget to invest in safety pins or fabric clips to hold pieces in place—these simple tools can save you time and frustration.

Tips: Always keep your workspace organized. A clutter-free area allows you to focus on your sewing and prevents accidents. Moreover, regularly maintain your machine by cleaning and oiling it as recommended by the manufacturer; this will extend its lifespan and optimize performance. Take the time to familiarize yourself with each tool, as mastering them will greatly enhance your textile crafting journey.

Understanding the basic functions and features of a mini textile machine is crucial for beginners looking to maximize efficiency and creativity in their textile projects. Most mini textile machines are designed to be user-friendly, incorporating essential functions such as sewing, stitching, and sometimes even embroidery. According to a report by IBISWorld, the demand for textile machinery is expected to grow by approximately 3.5% annually, indicating an increasing interest in personalized crafting and small-scale textile production.

Beginners should familiarize themselves with common features such as adjustable stitch settings, built-in tutorials, and easy threading mechanisms. A survey by The Association of Sewing and Crafting Enthusiasts found that nearly 60% of new users struggle with machine setup, highlighting the importance of understanding these basic functions. Additionally, many models come with multiple presser feet to accommodate various fabrics, which can enhance creativity. By mastering these essential features, beginners will be more equipped to produce high-quality textile items efficiently, tapping into the rising trend of DIY and custom fashion.

Setting up a mini textile machine for the first time can be both exciting and intimidating. To help you get started, follow this step-by-step guide that will streamline the process. First, ensure that you have a clean and organized workspace with adequate lighting. Unpack your mini textile machine and read through the user manual thoroughly to familiarize yourself with its components.

Next, begin the setup by attaching key parts such as the needle, thread, and bobbin. Make sure to thread the machine correctly, as improper threading can lead to poor stitching quality. Once set up, test the machine with some scrap fabric to adjust the stitch length and tension. This will help you better understand how the machine operates and allow you to make any necessary adjustments before starting your actual projects.

Tips: Always keep your sewing area tidy and have essential tools like scissors and fabric pins within reach. Additionally, practice sewing straight lines and curves on scrap fabric, as this builds your confidence and skills. Don’t forget to maintain your machine regularly, as proper care ensures longevity and optimal performance.

Operating a mini textile machine can be a rewarding endeavor for beginners, but it can also come with its own set of challenges. It's essential to understand some common issues that may arise during operation and how to troubleshoot them effectively. According to a report from the International Textile Manufacturers Federation, nearly 30% of new textile machine users face operational difficulties within their first few months. This statistic underscores the importance of being well-prepared and informed about troubleshooting.

One frequent issue beginners encounter is thread tension problems. If the fabric bunches up or the stitches appear uneven, adjusting the tension can resolve this. Start by checking the tension dial; it’s often beneficial to use a tension gauge for accurate adjustments. Additionally, ensuring the thread is correctly threaded through the machine can prevent these issues. A study from the Textile Research Journal indicates that proper threading can reduce operational hiccups by up to 40%, illustrating the critical nature of this initial step.

Another common problem is the machine jamming. This can happen due to a variety of reasons, such as lint accumulation or incorrect needle insertion. Regular cleaning of the bobbin case and ensuring that the needle is inserted the right way can significantly reduce the likelihood of jams. Reports from the Association of Sewing Machine Manufacturers indicate that regular maintenance can extend the lifespan of these machines by as much as 50%, emphasizing the importance of routine checks and proactive measures in troubleshooting.

Maintaining your mini textile machine is crucial for ensuring its longevity and optimal performance, especially for beginners. First and foremost, regular cleaning is essential. Dust and fabric residues can accumulate in the machine, leading to potential jams or malfunctions. After every use, take the time to remove any leftover threads and lint. A gentle brush can help clear out debris from the nooks and crannies. Additionally, refer to your machine’s manual for specific cleaning instructions, as different models may have unique requirements.

Lubrication is another best practice that should not be overlooked. Many mini textile machines have moving parts that require lubrication to function smoothly. Using the recommended oil on the specified components can reduce wear and tear, ensuring that the machine operates efficiently. It’s advisable to check the machine regularly for any signs of friction or unusual noise, which may indicate that lubrication is needed.

Lastly, always store the machine in a dry, dust-free environment to protect it from environmental factors that could cause deterioration. By following these maintenance tips, beginners can enjoy a longer lifespan and better performance from their mini textile machines.