Leave Your Message

The textile industry is on the brink of a transformative evolution, largely driven by advancements in technology, particularly through the development of High Speed Carding Machines. These innovative machines are set to revolutionize the production processes, significantly enhancing efficiency and productivity in textile manufacturing. As the demand for rapid and high-quality fabric production grows, the role of high speed carding technology becomes increasingly crucial. This blog will explore the myriad benefits of integrating High Speed Carding Machines into textile production, including reductions in processing time, cost savings, and improved consistency in product quality. By examining the potential of these advanced machines, we will illustrate how they are not only reshaping industry standards but also paving the way for smarter, more sustainable manufacturing practices that meet the needs of the modern market.

The textile industry is on the cusp of a transformative era, largely driven by innovations in high-speed carding technology. Key advancements in machinery design, materials science, and automation are significantly enhancing production efficiency. Recent reports indicate that the global market for carding machines is projected to grow at a compound annual growth rate (CAGR) of approximately 5.5% between 2023 and 2028. This growth is a testament to the increasing demand for faster, more efficient textile production processes that can meet consumer needs while optimizing resource utilization.

A prominent figure in this innovation landscape is Xu Haiyan, whose relentless dedication to technological breakthroughs has led her team to overcome substantial technical challenges in the textile sector. Under her leadership, they have harnessed cutting-edge technologies to elevate the performance of high-speed carding machines. These innovations include the integration of advanced sensors for real-time quality monitoring and the deployment of AI for predictive maintenance, which not only reduce downtime but also enhance product quality. This combination of human ingenuity and technological prowess is paving the way for a new chapter in textile manufacturing, ensuring that the industry remains competitive in an ever-evolving marketplace.

| Innovation | Description | Benefits | Impact on Efficiency |

|---|---|---|---|

| Automated Feeding Systems | Integration of automation in fiber feeding to enhance input consistency. | Reduces manual labor and errors, leading to consistently better quality. | Increases overall production speed by up to 20%. |

| Smart Monitoring Systems | Implementation of IoT sensors to monitor machine performance in real-time. | Facilitates predictive maintenance, reducing downtime. | Potentially improves operational efficiency by 30%. |

| Advanced Carding Geometry | Innovative designs in roller and cylinder configurations for better fiber alignment. | Maximizes fiber opening and blending efficiency. | Boosts production quality and speeds by reducing waste. |

| Energy-Efficient Motors | Adoption of high-efficiency motors designed to reduce energy consumption. | Lowers operational costs and environmental impact. | Sustains productivity while cutting energy usage by up to 15%. |

| Variable Speed Drives | Utilization of variable speed drives to optimize machine speed according to fiber type. | Enhances adaptability to different production needs. | Enhances production flexibility and throughput. |

The textile industry is witnessing a transformative shift with the advent of modern high-speed carding machines. These machines not only enhance production rates but also significantly improve the quality of carded fibers. According to a report from the Textile World Journal, advanced carding technologies can increase throughput by up to 40%, reducing the time required to process raw materials. This efficiency is crucial for manufacturers looking to keep pace with market demands and respond to consumer trends swiftly.

The textile industry is witnessing a transformative shift with the advent of modern high-speed carding machines. These machines not only enhance production rates but also significantly improve the quality of carded fibers. According to a report from the Textile World Journal, advanced carding technologies can increase throughput by up to 40%, reducing the time required to process raw materials. This efficiency is crucial for manufacturers looking to keep pace with market demands and respond to consumer trends swiftly.

Furthermore, the modern carding machines integrate smart technology, allowing for real-time monitoring and adjustments. A study published by the International Textile and Apparel Association highlights that such innovations can minimize waste by as much as 30%, driving sustainability in textile production. The machines are increasingly equipped with automatic settings that optimize fiber handling, ensuring consistency in quality and reducing labor costs associated with manual interventions. As industry leaders adopt these high-speed carding solutions, the potential for improved efficiency and quality in textile manufacturing becomes not only a goal but an achievable reality.

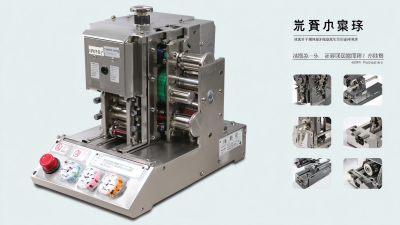

When selecting high-speed carding equipment, several essential features can significantly impact textile production efficiency. Firstly, automation capabilities are crucial; advanced carding machines now incorporate intelligent systems that enhance operational speed and maintain consistent quality. Look for machines equipped with programmable interfaces that allow operators to easily adjust settings for different fibers and production runs, ensuring versatility and reducing downtime.

Another key feature is the quality of the carding cylinder and the doffing system. High-quality components minimize fiber damage while maximizing processing efficiency. Additionally, machines with effective dust removal and maintenance systems not only prolong the lifespan of the equipment but also ensure a cleaner production environment.

Finally, consider the machine’s compatibility with modern data analytics tools. Integrating IoT capabilities allows for real-time monitoring of machine performance, facilitating proactive maintenance and enabling manufacturers to optimize their production workflows. Investing in high-speed carding machines with these essential features can transform textile manufacturing processes, driving efficiency and productivity to new heights.

The textile industry is witnessing a remarkable transformation driven by automation, particularly in the realm of high-speed carding machines. These machines play a critical role in the initial stages of textile production by untangling, cleaning, and blending fibers. With advancements in automation technology, manufacturers are now able to enhance the efficiency and precision of carding processes, resulting in higher-quality output and reduced operational costs.

One of the most significant impacts of automation on carding machine efficiency is the reduction of human error and the need for manual labor. Automated systems can operate continuously with minimal oversight, allowing for consistent quality and increased production rates. Moreover, innovations such as real-time monitoring and smart sensors enable these machines to optimize their performance dynamically, adjusting to varying fiber types and conditions. This level of adaptability not only increases the speed of production but also ensures a more sustainable approach by minimizing waste and energy consumption.

As the industry continues to embrace these automated solutions, the future of high-speed carding machines looks promising. The integration of advanced technologies such as artificial intelligence and machine learning is expected to further refine these processes, pushing the boundaries of efficiency and effectiveness in textile production. The era of automated carding machines is not just about faster production; it's about revolutionizing the entire textile manufacturing landscape.

The textile industry is on the brink of a significant transformation, largely driven by advancements in carding machine technology. The application of automation, digitization, and sustainable practices is becoming increasingly prevalent. Recent market reports indicate that the needlepunch technology has experienced a surge in orders, reflecting a rebound in demand post-pandemic. This trend underscores a broader shift towards efficiency, where continuous innovation plays a critical role in enhancing production capabilities.

One notable development is the integration of sustainable materials into the carding process. For instance, experiments with pineapple leaf fiber (PALF) and recycled waste fibers are paving the way for new eco-friendly yarns. The importance of sustainability in textile production is highlighted by a report showcasing how bamboo fiber reinforced polymeric composites are emerging as viable alternatives, promoting a circular economy within the industry.

Furthermore, as industry leaders embark on showcasing futuristic spinning solutions, it reflects an acknowledgment of the pressing need for green technologies in manufacturing. This direction points towards significant advancements in not just machine performance but also in aligning production processes with environmental sustainability goals, which is becoming an essential consideration for future textile production.