Leave Your Message

The textile manufacturing industry is on the cusp of a significant transformation, driven by advancements in technology and evolving consumer demands. Among the numerous innovations reshaping this landscape, the padding machine textile technology stands out as a crucial element in enhancing production efficiency and product quality. As manufacturers seek to optimize their operations and remain competitive in a fast-paced market, understanding the future of padding machine technology becomes imperative. This blog will delve into the top strategies that companies can adopt to harness the full potential of padding machines, ensuring that they not only meet industry standards but also exceed customer expectations. From automation and smart technology integration to sustainable practices, we will explore how embracing these strategies can propel the textile manufacturing sector into a new era of productivity and innovation.

The textile manufacturing industry is undergoing significant transformations, driven by key innovations in padding machine technology. One notable advancement is the Cold Pad Batch dyeing process, which enhances color quality while reducing water and energy consumption. The integration of this technology allows for more sustainable production practices that align with global environmental standards, making it a vital consideration for manufacturers aiming to minimize their ecological footprint.

Furthermore, the incorporation of smart textiles in padding techniques represents another leap forward. Innovations such as seamless integration of functional yarns into garments not only elevate product functionality but also cater to the growing demand for wearable technology. These developments highlight a trend towards systems that enable manufacturers to produce high-quality textiles efficiently, ultimately benefiting the end consumer through enhanced wearability and performance. As the industry progresses, the importance of adopting cutting-edge padding machine technologies becomes increasingly clear, paving the way for a more sustainable and innovative future in textile manufacturing.

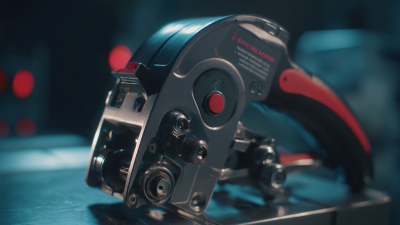

Padding machines play a crucial role in the textile manufacturing process, providing a variety of applications to enhance fabric properties. Primarily, there are two types of padding machines: double-dip machines and single-dip machines. Double-dip machines immerse fabrics in a padding solution twice, ensuring maximum absorption of chemicals, which is essential for processes like dyeing and finishing. Single-dip machines, on the other hand, are more suited for lighter treatments and are often used for pre-treatment applications, making them ideal for less complex fabric requirements.

When choosing the right padding machine for your operation, consider the type of fabric you are working with and the desired result. For heavier fabrics that require thorough treatment, a double-dip machine might be the best choice. Conversely, for lighter textiles, a single-dip may offer a more efficient solution. Additionally, keeping your machines well-maintained and regularly calibrated can greatly enhance their efficiency and longevity.

Another tip is to stay updated on technological advancements in padding machines. As automation and digital control systems evolve, they can lead to greater precision and efficiency in the padding process, which ultimately contributes to lower production costs and improved fabric quality. Adapting to these changes can place your textile manufacturing ahead of the competition.

In the textile manufacturing industry, the integration of automation into padding processes is reshaping the landscape of production efficiency and quality control. A recent report by McKinsey & Company highlights that automation can boost productivity in textile operations by up to 30%. This substantial gain is particularly evident in the padding stage, where precision and consistency are critical. The use of automated padding machines minimizes human error and maximizes output, allowing companies to meet the increasing demand for high-quality fabrics more effectively.

Moreover, the recent advancements in machine learning and artificial intelligence are driving the evolution of padding technologies. Research by the International Textile Manufacturers Federation (ITMF) indicates that companies investing in automated solutions can expect a reduction in overall production costs by approximately 20%. This cost-effectiveness, coupled with the enhanced capability for real-time monitoring and adjustments, presents a compelling case for the transition towards automated padding processes. As the industry adapts to these technological innovations, the potential for improved sustainability and reduced waste becomes increasingly apparent, paving the way for a more efficient future in textile manufacturing.

The textile manufacturing industry is increasingly embracing sustainability trends, particularly in the realm of padding machine technology. According to a report by the Research Institute of Textile Technology, approximately 30% of the energy consumed in textile production is attributed to padding processes. However, innovative padding machines now incorporate energy-efficient systems that can reduce this consumption by up to 25%. Furthermore, the integration of automation and smart technologies in these machines facilitates better resource management, resulting in less waste during the manufacturing phase.

Moreover, sustainable materials are gaining traction in the padding machine sector. Data from the Global Cotton Sustainability Initiative indicates that the use of organic and recycled materials in padding processes has risen by 15% over the past three years. This shift not only enhances the eco-friendliness of textile products but also aligns companies with consumer preferences for sustainable goods. As padding machine technology evolves, it offers new solutions that not only improve productivity but also significantly minimize environmental impact, paving the way for a greener future in textile manufacturing.

The textile industry is rapidly evolving, and padding machine technology is at the forefront of this transformation.

According to a recent report by MarketsandMarkets, the global textile machinery market is projected to reach $26.4 billion by 2027,

growing at a CAGR of 4.5%. This growth is driven by increasing demand for advanced textile machinery that enhances

productivity and sustainability in the manufacturing process.

Padding machines, which are essential in applying finishes to fabrics, will play a vital role in meeting these industry

demands, especially as manufacturers shift towards eco-friendly practices.

Future trends indicate that padding machines will incorporate more automation and digitalization to optimize

production efficiency. Industry experts suggest that the adoption of

Industry 4.0 technologies, such as IoT and AI, can revolutionize padding processes by enabling real-time

monitoring and predictive maintenance. Additionally, new developments in padding chemicals that are less harmful to the environment are

expected to gain traction, as brands increasingly focus on sustainability. The combination of these innovations will not only reduce waste

but also enhance the quality of textile products, positioning padding machines as indispensable tools in the evolution of the textile

manufacturing landscape.