Leave Your Message

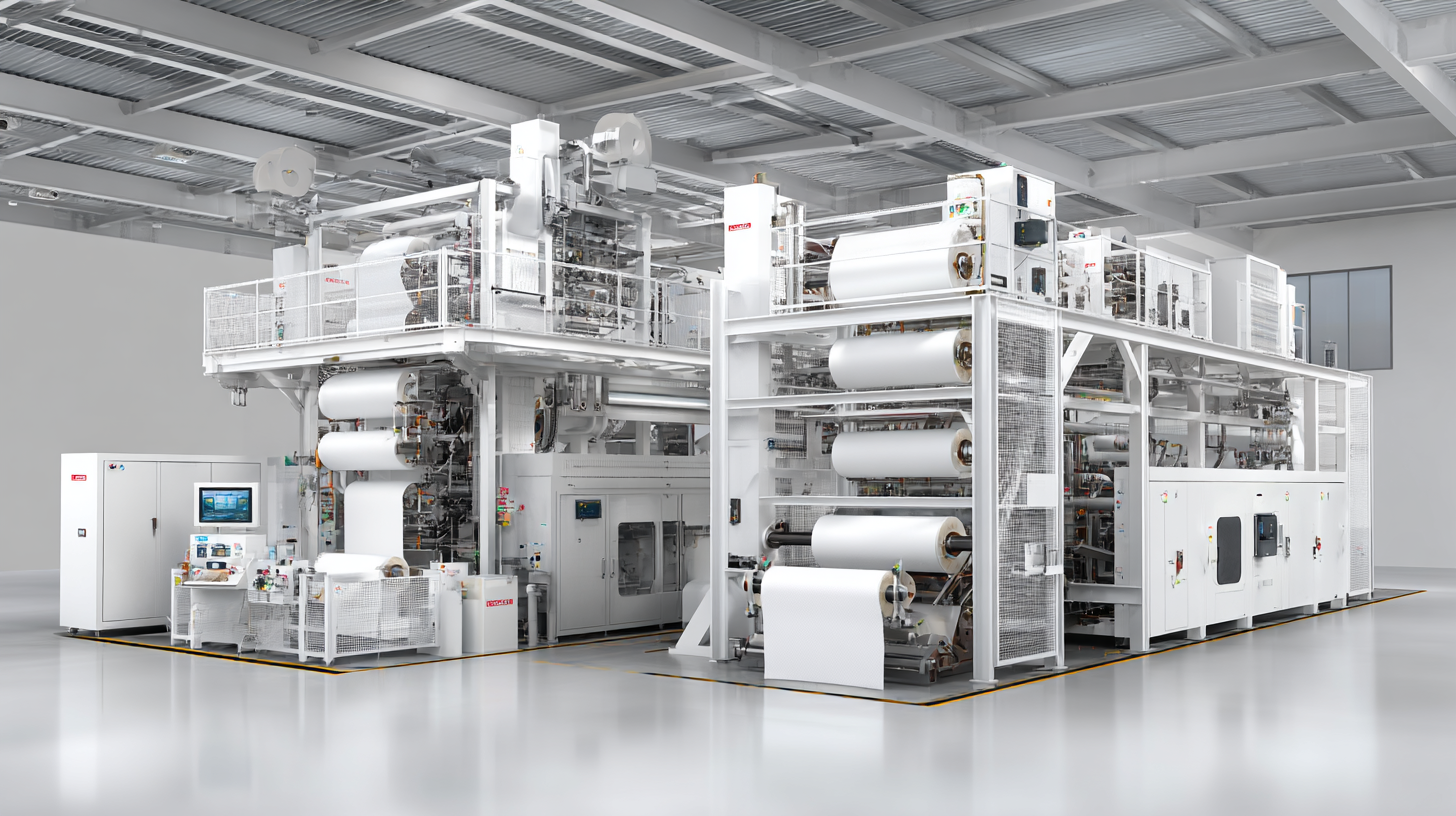

In the rapidly evolving textile industry, understanding the nuances of manufacturing equipment is paramount for optimizing production efficiency. The Automatic Spunlace Line has emerged as a key technology for producing nonwoven fabrics that are widely used in various applications, from hygiene products to industrial wipes.

According to a recent report by Smithers Pira, the global nonwoven fabric market is expected to reach $50 billion by 2027, driven by increasing demand for disposable products and sustainable solutions.

As manufacturers seek to enhance their productivity while minimizing waste, selecting the right Automatic Spunlace Line tailored to specific product characteristics and requirements becomes crucial.

This ultimate guide aims to explore the distinct features of different types of spunlace lines, their applicable scopes, and practical insights on how to choose the best options to meet your manufacturing needs effectively.

When evaluating suppliers for automatic spunlace lines, several key factors should be at the forefront of your decision-making process. First, it is essential to assess the supplier's experience and expertise in the industry. A reputable supplier should have a proven track record of delivering high-quality machinery and support services. Look for testimonials and case studies that highlight the supplier's ability to meet the specific manufacturing needs of businesses similar to yours.

Another critical aspect to consider is the level of customization offered. Your manufacturing needs may vary significantly based on the product specifications and production volume. A supplier that can provide tailored solutions will be better equipped to address your unique requirements, ensuring that the spunlace line integrates seamlessly into your production process. Additionally, don’t overlook after-sales support, including maintenance services and training for your staff; strong ongoing support is vital for maximizing your investment’s longevity and performance.

When selecting an automatic spunlace line for your manufacturing needs, understanding production capacity and quality standards is paramount. The production capacity of a spunlace line directly influences your operational efficiency and ability to meet market demands. Before making a decision, it’s crucial to assess your current production volume and growth projections. An ideal spunlace line should not only fulfill your immediate capacity needs but also allow for scalability. Choose a manufacturer that provides options for both high-speed production and the ability to adapt to various material inputs, ensuring flexibility in your operations.

Equally important are the quality standards upheld by the spunlace industry. These standards ensure that the final product meets the necessary specifications for various applications, from medical to industrial uses. Investigate the certifications and quality control measures implemented by the manufacturer of the spunlace line. Look for features such as online monitoring systems, automated quality checks, and compliance with internationally recognized standards to guarantee the consistency and reliability of your products. Ensuring adherence to these quality benchmarks will not only enhance your product's market competitiveness but also strengthen your brand's reputation among consumers.

When selecting the best automatic spunlace line for your manufacturing process, one of the critical factors to consider is the compliance of your suppliers with established certifications and standards. In today's global market, particularly in industries such as medical devices, adhering to regulations like the EU MDR and IVDR is paramount. These regulations not only ensure that products meet safety and performance requirements but also protect your business from the risks associated with substandard materials. For manufacturers, working with suppliers who have robust compliance frameworks instills confidence in the quality and integrity of the raw materials being used.

Furthermore, the importance of maintaining ethical compliance extends beyond just regulatory adherence. Businesses are increasingly held accountable for their supply chains, and proactive management of compliance can significantly mitigate risks associated with operational disruptions. For example, enhancing safety behavior through diligent supply chain management can lead to improved safety outcomes and greater operational resilience. As industries face evolving regulations and scrutiny, companies must prioritize partnerships with certified suppliers who demonstrate a commitment to compliance and ethical practices, ensuring a sustainable and efficient manufacturing environment.

In the rapidly evolving landscape of manufacturing, the significance of technological advancements in automatic spunlace production cannot be overstated. Manufacturers are increasingly turning to these innovations to enhance efficiency, improve product quality, and reduce operational costs. Key advancements include the integration of AI-driven automation, which optimizes the production process by monitoring real-time data, predicting maintenance needs, and minimizing downtime, thus ensuring a smoother workflow.

Moreover, advancements in materials technology have led to the development of more durable and efficient spunlace lines. Innovations such as eco-friendly fibers and enhanced filtration systems not only improve the quality of the final product but also align with sustainability objectives in manufacturing. As businesses adapt to stricter environmental regulations, the shift towards greener technologies will likely play a pivotal role in the future of automatic spunlace production, making it crucial for manufacturers to stay updated on these developments to remain competitive.

When selecting an automatic spunlace line for your manufacturing operations, the reliability of your supplier is paramount. An assessment of customer reviews and case studies can provide invaluable insights into the vendors' performance and product quality. According to a recent report from Smithers Pira, 74% of manufacturers prioritize supplier reliability as one of their top criteria when purchasing new machinery. Analyzing customer feedback can help you gauge the consistency of performance and customer support provided by potential suppliers.

Case studies further reinforce the importance of this assessment. For example, a prominent spunlace manufacturer reported a 20% increase in production efficiency after switching to a new supplier, as detailed in a 2022 industry analysis by Frey & Associates. This shift was attributed to not just superior technology, but also the excellent after-sales service, which was highlighted by multiple customer testimonials. By closely examining such reviews and documented success stories, businesses can make informed decisions that lead to improved operational outcomes and reduce the risks associated with procurement.