Leave Your Message

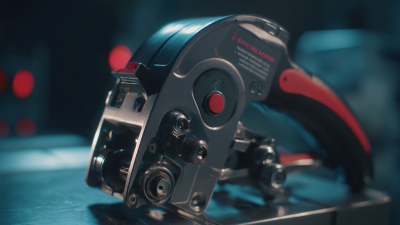

In today's fast-paced manufacturing environment, the selection of tools can significantly impact productivity and quality. Among these tools, the Professional Crimping Machine stands out as an essential device for ensuring precise and durable connections in various applications, from electrical wiring to automotive components. However, with the plethora of options available in the market, choosing the right crimping machine can be a daunting task. This guide aims to demystify the decision-making process by providing comprehensive insights into the key factors to consider, including machine specifications, application needs, and budget constraints. Whether you are a seasoned professional or a newcomer to the industry, understanding the nuances of different models and features will empower you to make an informed choice that fits your operational demands and enhances your overall efficiency. Join us as we explore the intricacies of selecting the ideal Professional Crimping Machine for your specific needs.

When it comes to selecting the right crimping machine, understanding the diverse types available for various applications is essential. Crimping machines are integral to multiple industries, from electronics to food packaging. Each type of machine caters to specific requirements, influenced by the materials being processed and the desired strength of the connections. For instance, heat sealing machines focus on ensuring seal integrity in flexible food packages, which is critical for maintaining product freshness and safety. The effectiveness of these machines can significantly impact the quality of the final product.

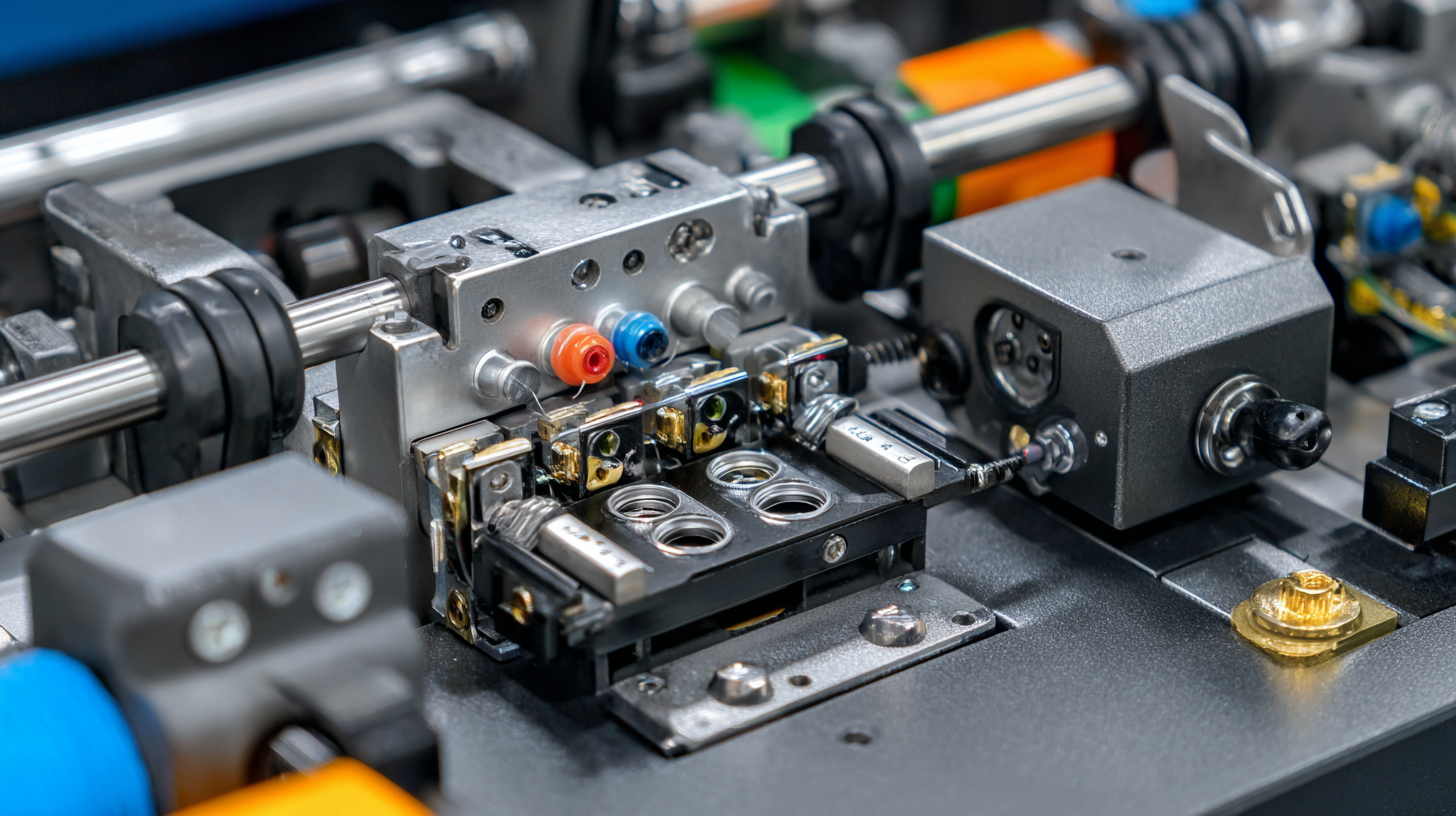

In the realm of electrical connections, the choice between different crimping tools such as ratchet crimp pliers and simpler crimp pliers can dramatically affect the outcome. Testing has shown that the precision of crimping is vital for ensuring reliable performance, particularly in fields like electric vehicle charging, where crimp pin connectors play a pivotal role in power transfer efficiency. Additionally, automating the crimping process can increase productivity and quality, underscoring the importance of selecting a machine that not only meets structural requirements but also enhances operational efficiency in production settings.

When selecting a professional crimping machine, it’s crucial to focus on key features that enhance precision and efficiency. First, consider the machine's crimping capacity, which encompasses wire sizes and types it can handle. A versatile crimping machine should accommodate a range of materials, including various gauges of wire and connectors, to meet diverse project requirements.

Additionally, look for machines with adjustable crimping force settings, allowing the user to customize the pressure applied for different applications, ensuring consistent and reliable crimping results.

Additionally, look for machines with adjustable crimping force settings, allowing the user to customize the pressure applied for different applications, ensuring consistent and reliable crimping results.

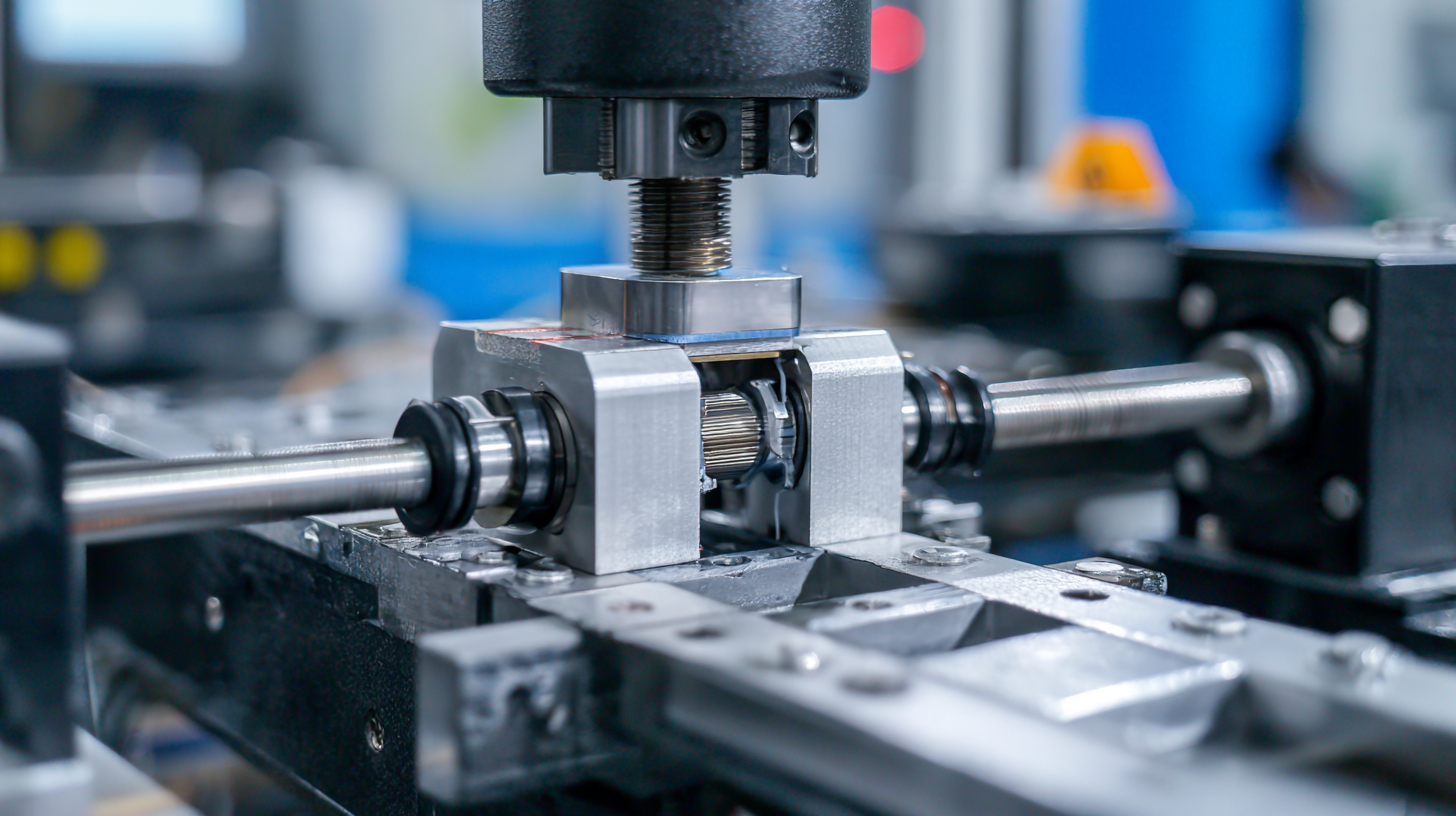

Another significant feature to examine is the ease of use and workflow efficiency. Machines equipped with user-friendly interfaces and automatic crimping mechanisms can significantly streamline operations, reducing the time spent on setup and execution. Moreover, durability and build quality play an essential role; invest in a crimping machine made from robust materials that can withstand repetitive use over time.

Finally, consider the availability of additional features such as interchangeable dies, built-in safety mechanisms, and compatibility with software for process tracking, all of which contribute to enhanced performance and user experience.

When choosing between manual and electric crimping machines, several factors come into play, including efficiency, ease of use, and the specific application requirements. According to the 2022 Crimping Machine Market Report, electric crimpers are gaining popularity due to their ability to handle high-volume tasks with precision and consistency, achieving a 30% increase in production speed compared to manual machines. However, for small-scale operations or those requiring portability, manual crimpers remain a viable option, offering simplicity and lower upfront costs.

Tips: If you frequently work with different wire sizes, consider a machine with adjustable dies for better versatility. Moreover, electric machines often come equipped with automated features, which can significantly reduce operator fatigue during long runs.

While electric crimping machines can provide a seamless workflow and minimize the risk of human error, they require a higher investment. The choice largely depends on the production demands of your business. For hobbyists or occasional use, a manual crimper may suffice, as it allows for more hands-on control without the need for electrical outlets or maintenance concerns. Understanding your operational requirements will guide your decision towards the best tool for your needs.

When using professional crimping equipment, safety should always be the top priority. Crimping machines can pose various hazards if not handled properly, so it’s essential to follow strict safety guidelines. Always wear appropriate personal protective equipment (PPE), including safety glasses and gloves, to avoid injuries from flying debris or sharp edges. Additionally, ensure that the work area is clean and free of clutter, reducing the risk of tripping or falling while operating the machine.

**Tips:** Before starting any crimping task, perform a thorough inspection of the equipment. Check for any signs of wear or damage, and maintain all moving parts in good condition. Familiarize yourself with the machine’s user manual to understand its safety features and operational limits. Keeping your workspace organized and free from distractions can also help maintain focus during crimping tasks, ensuring a safer working environment.

Proper training is another crucial aspect of safe crimping practices. Ensure that all operators are adequately trained in the specific machinery they will be using. Regular safety briefings and refreshers on crimping techniques and emergency procedures can help reinforce the importance of safety and keep everyone alert to potential risks. Remember that safety is an ongoing commitment that should be integrated into your daily operations.

To ensure that your crimping machine operates with precision and durability, regular maintenance is essential. According to a report by the International Organization for Standardization (ISO), well-maintained equipment can lead to a 30% increase in efficiency. This highlights the importance of establishing a routine maintenance schedule that includes cleaning, lubrication, and inspection of critical components.

Tips: Implement a monthly cleaning regimen for your crimping machine. Dust and debris can accumulate and affect performance. Additionally, check for any signs of wear on the crimping dies and replace them as needed to maintain precision.

Moreover, it is crucial to store your crimping machine in a controlled environment. Maintaining stable temperature and humidity levels can prevent rust and other forms of corrosion. A study conducted by the Institute of Electrical and Electronics Engineers (IEEE) suggested that optimal storage conditions can prolong the lifespan of machinery by up to 20%.

Tips: Use protective covers and consider climate control if your workspace is prone to extremes. This small investment in your machine's environment can yield significant returns in performance consistency and longevity.

| Dimension | Specification | Maintenance Tips |

|---|---|---|

| Crimping Capacity | Up to 10 mm² | Regularly inspect and clean crimping dies to avoid buildup. |

| Power Source | Electric or Manual | Ensure electrical connections are secure and free of debris. |

| Weight | Varies (typically 2-5 kg) | Store in a dry place to prevent corrosion. |

| Crimping Speed | Up to 500 crimps/hour | Keep all moving parts lubricated but avoid over-lubrication. |

| Die Types | Interchangeable dies for various connectors | Use the correct die for the application to ensure reliability. |

| Warranty Period | 1-3 years | Review warranty terms to understand maintenance obligations. |