Leave Your Message

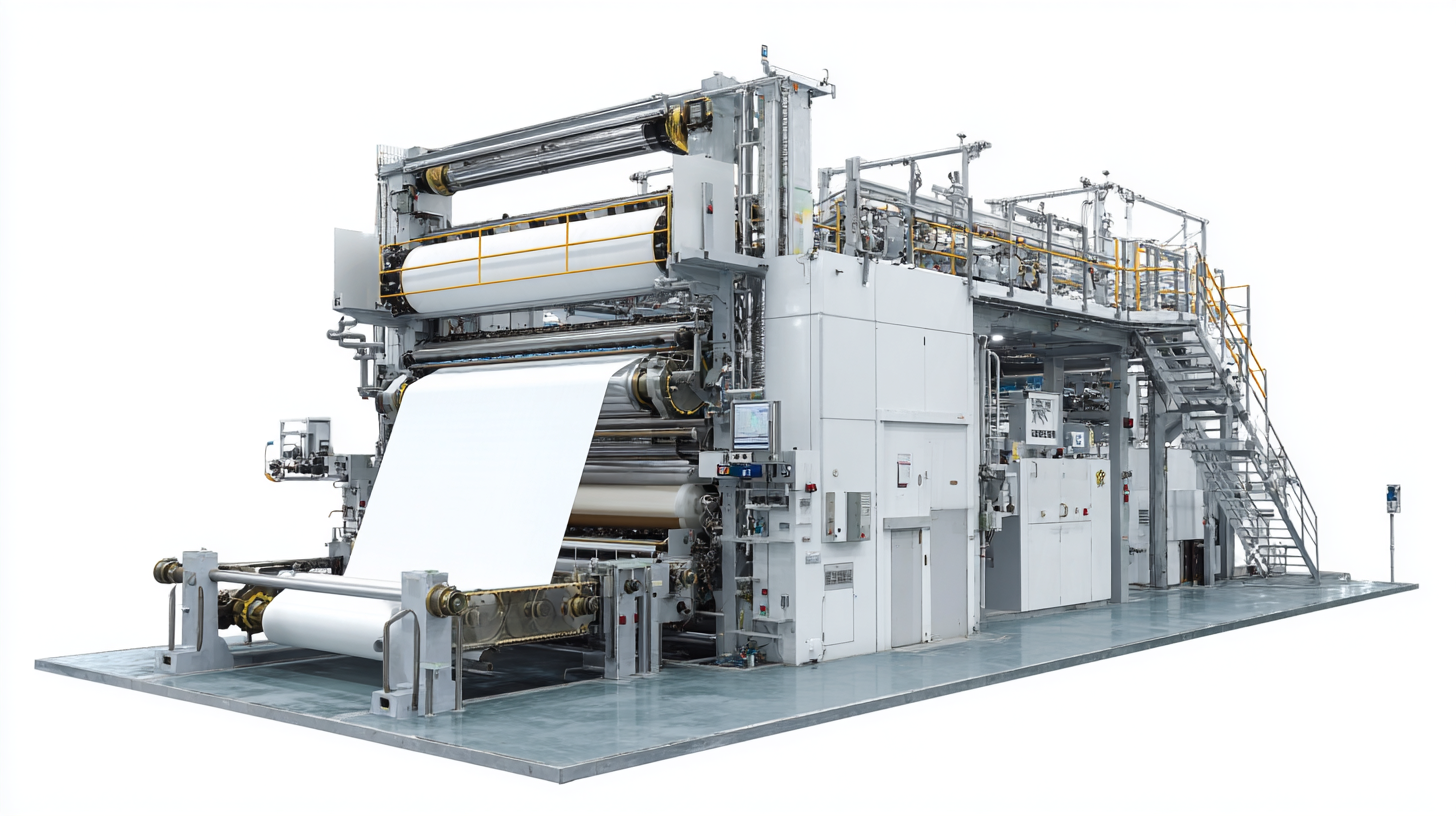

In the global textile industry, the demand for high-quality fabrics continues to soar, with the market projected to reach $1 trillion by 2025, according to a report by Smithers Pira. Central to this growth is the role of advanced "Textile Processing Machines," which facilitate efficient production while ensuring precision craftsmanship. Chinese manufacturers have emerged as key players, leveraging innovative technologies to meet the diverse needs of international markets. A recent analysis by Technavio highlights that the textile machinery market will grow at a CAGR of over 5% from 2021 to 2025, underscoring the importance of adopting top strategies for enhancing machine efficiency and output quality. This blog will delve into the best practices that can drive success in the textile processing sector, ensuring that manufacturers can compete effectively on a global scale.

The textile industry, steeped in history, is currently witnessing a transformative wave led by precision craftsmanship in machinery. Chinese manufacturers are at the forefront of this shift, enhancing the efficiency and accuracy of textile processing machines. This rise in precision allows brands across the globe to produce higher-quality fabrics while minimizing waste and maximizing productivity. The integration of advanced technologies results in machines capable of meticulous embroidery and weaving, redefining standards in textile production.

Tip: When investing in textile processing machines, consider those equipped with digital technology that offers real-time data analytics. This can greatly improve your operational efficiency.

Furthermore, the Schiffli embroidery machine market exemplifies this trend, with projections indicating significant growth over the next decade. The demand for precision in decorative stitching reflects a broader shift towards quality and customization in the textile sector. As Chinese manufacturers focus on precision craftsmanship, they are not only meeting local needs but are also poised to capture a larger share of global markets.

Tip: Explore partnerships with suppliers who prioritize innovation and sustainability in their manufacturing processes. This can enhance your brand's value while ensuring eco-friendly practices.

| Machine Type | Feature | Precision Level | Market Demand (%) | Export Growth Rate (%) |

|---|---|---|---|---|

| Automatic Fabric Cutting Machine | High-speed cutting with sensors | ±0.1 mm | 80% | 15% |

| Multi-functional Knitting Machine | Versatile patterns and fabrics | ±0.05 mm | 75% | 20% |

| Digital Printing Machine | High-resolution prints | ±0.01 mm | 85% | 25% |

| Laser Cutting Technology | Precision and intricate designs | ±0.02 mm | 70% | 18% |

| Textile Finishing Equipment | Enhanced durability and finish | ±0.1 mm | 65% | 12% |

Precision craftsmanship in textile processing machines from China has propelled these innovations to serve global markets effectively. The advancement of technology in this sector not only enhances production efficiency but also bolsters competitiveness on a worldwide scale. As industries across the globe recognize the importance of technological expertise, Chinese manufacturers are stepping up by integrating cutting-edge technologies in their machines. This not only aligns with global standards but also enables businesses to tap into new markets and opportunities.

To enhance your own competitiveness, consider these tips: first, invest in research and development to stay ahead of the curve. Emphasizing innovation can set your brand apart in a crowded market. Secondly, embrace sustainability. As industries shift towards cleaner technologies, aligning your practices with environmental goals can provide a distinct edge. Lastly, build strategic partnerships. Collaborating with other innovators can lead to shared knowledge, resources, and increased market reach, ultimately strengthening your position in the global marketplace.

This chart illustrates the market competitiveness of various innovative textile processing technologies from China, showcasing the production output in millions of units over the past five years.

The textile industry is witnessing a significant shift as manufacturers seek equipment that not only meets their quality standards but is also adaptable to their unique production requirements. In this landscape, Chinese textile processing machines stand out by offering customizable solutions that cater to diverse needs. From weaving and dyeing to finishing processes, these machines can be tailored to accommodate various fabric types, production volumes, and operational workflows. This flexibility allows businesses to remain agile in a rapidly changing market while optimizing their efficiency.

Customization in textile machinery goes beyond mere adjustments; it encompasses the integration of advanced technology to enhance performance. Manufacturers can work closely with Chinese suppliers to specify features that align with their production goals, whether it’s implementing automated systems for increased productivity or designing user-friendly interfaces to streamline operations. This bespoke approach not only improves the functionality of the machines but also enables manufacturers to differentiate their products in a competitive global market. By investing in customizable textile processing equipment, companies can ensure that they are well-equipped to adapt to the evolving demands of consumers and trends in the textile industry.

Sustainability has become a pivotal concern in the textile manufacturing industry, and Chinese manufacturers are stepping up to the challenge by adopting eco-friendly practices. As consumers worldwide increasingly demand sustainable products, the textile sector is responding by integrating innovative technologies and materials that minimize environmental impact. This shift not only enhances the quality of textile processing machines but also aligns with the global movement towards responsible production.

In recent years, Chinese companies have prioritized the development of textiles from recyclable and organic materials, significantly reducing waste and energy consumption. Moreover, advanced textile processing machines now feature cutting-edge solutions such as waterless dyeing technology and energy-efficient manufacturing processes. These innovations help to lower the carbon footprint associated with textile production while ensuring high-quality output. By investing in these sustainable practices, Chinese manufacturers are not only improving their competitive edge in global markets but are also contributing to a greener future for the industry as a whole.

The global textile machinery market is undergoing significant transformation, propelled by an increasing demand for high-quality textile products and innovations in processing technologies. According to a report by Research and Markets, the global textile machinery market was valued at approximately $23 billion in 2020, with expectations to reach around $30 billion by 2026, growing at a CAGR of 5.5%. This burgeoning market opens up avenues for Chinese manufacturers who are renowned for their precision craftsmanship and advanced machinery, positioning them favorably for international competitiveness.

However, the path is not without challenges. Issues such as rising raw material costs and trade tensions significantly impact the cost structure and market accessibility for Chinese textile machinery exporters. A report from Technavio suggests that global supply chain disruptions can lead to increased lead times and operational inefficiencies. Moreover, while China's textile machinery industry has advanced, the push for sustainability mandates that manufacturers innovate in areas such as eco-friendly production techniques and energy-efficient machines. This dual pressure of meeting global sustainability standards while upholding manufacturing excellence presents both a challenge and an opportunity for companies aiming to solidify their presence in the global market.