Leave Your Message

In the rapidly evolving world of textile manufacturing, quality and efficiency are paramount, especially for global buyers seeking the best solutions. This blog will illuminate the unparalleled advantages of the Mini Textile Machine, a technological marvel that combines compact design with superior performance. As manufacturers in China continue to innovate, these machines are becoming essential tools for businesses looking to enhance production capabilities without incurring excessive costs. We’ll explore the after-sales service benefits and maintenance costs associated with these machines, ensuring you make informed decisions as you navigate the market. Additionally, we’ll provide practical tips to maximize the value and utility of your Mini Textile Machine, demonstrating why investing in this type of equipment can transform your textile operations for the better.

When considering the purchase of mini textile machines from China, one of the standout features is the robust after-sales service that complements the high-quality manufacturing. Buyers can expect a support system that ensures the seamless operation of their equipment. Chinese manufacturers are well-aware of the complexities that may arise in textile production, and they offer comprehensive after-sales services that include installation assistance, technical support, and timely maintenance. This level of commitment not only minimizes downtime but also enhances overall productivity for global buyers.

Moreover, the after-sales service landscape includes training programs tailored for operators, ensuring they are well-versed in the nuances of the machines they are using. This investment in customer training not only boosts machine efficiency but also empowers buyers to handle minor issues independently, fostering confidence in their investment. With such a strong support structure in place, global buyers can feel assured that their decision to invest in mini textile machines from China is backed by a dependable safety net, paving the way for successful and sustainable textile operations.

The textile industry is undergoing a significant transformation, with

data science playing a pivotal role in enhancing mini textile machines.

Understanding repair costs is paramount for global buyers looking to invest in these machines.

A comparative analysis can reveal how different brands and models vary in maintenance expenses. This can ultimately influence purchasing decisions,

as lower repair costs may indicate a machine's reliability and longevity, making it an attractive option

for operators in both domestic and commercial sectors.

Moreover, as the industry optimizes maintenance and quality control to meet the growing demands, buyers must consider the implications of

data-driven insights. These advancements not only lead to improved performance but also ensure that

operating costs are kept in check. By assessing the repair costs associated with various mini textile machines, global buyers can make informed decisions

that will benefit their operations and lead to long-term savings.

When selecting the right mini textile machine for your production needs, it’s essential to consider various factors that directly impact efficiency and output quality. According to a report by Grand View Research, the global textile machinery market is expected to reach USD 24.84 billion by 2025, driven by increasing demand for advanced machinery that can deliver high precision and minimize waste. Such advancements make mini textile machines not only an economical choice but also a viable option for small to medium enterprises looking for flexibility in manufacturing.

One of the primary considerations is the specifications of the machine itself. For instance, material compatibility, speed, and automation features all play a crucial role. Research from Technavio predicts that the mini segment of textile machinery will grow at a CAGR of 5% over the next few years, indicating a rising trend among manufacturers to invest in compact, efficient solutions. Buyers should also evaluate after-sales support and maintenance services, as these are critical for ensuring longevity and consistent performance of the equipment. By aligning your production requirements with the capabilities of these machines, you can enhance productivity while maintaining exceptional quality standards.

This chart illustrates the performance metrics of different mini textile machines based on production capacity and energy efficiency. Global buyers can use this information to make informed decisions when choosing the right machine for their production needs.

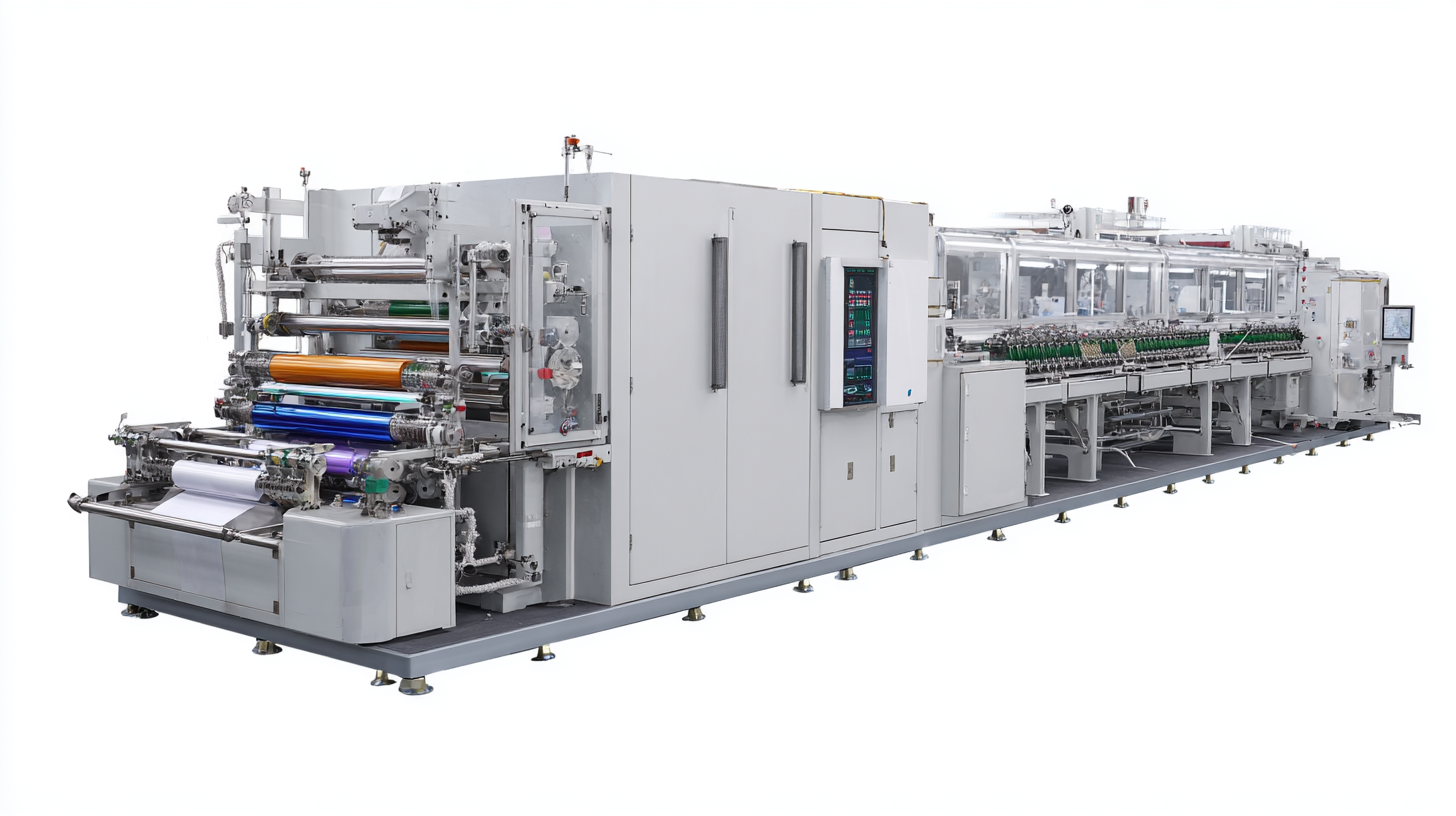

In recent years, mini textile machines have gained prominence as essential tools for businesses aiming to maximize efficiency in production. With the rise of Industry 4.0, manufacturers are increasingly integrating technology to streamline operations. Automated cutting and sewing solutions showcased at recent exhibitions like ITMA 2023 highlight this transition, leveraging advanced features that contribute to higher output and reduced labor costs. For instance, reports indicate that the adoption of automation in textile manufacturing can enhance production speed by as much as 30%, allowing businesses to respond quickly to market demands.

Key features of top mini textile machines include compact designs, energy efficiency, and user-friendly interfaces that enable seamless integration into existing workflows. Many models now come equipped with smart technology that provides real-time data analytics, enabling users to track performance metrics and make informed decisions on resource allocation. According to industry data, mini textile machines are critical in reducing waste and improving overall sustainability benchmarks in production, which is increasingly important for buyers looking to meet eco-friendly standards. As global buyers continue to seek innovative solutions, the demand for such high-quality machinery from China remains stronger than ever.

The mini textile machine market has witnessed significant growth in recent years, driven by the increasing demand for flexibility and efficiency in production. Global buyers are leaning towards mini textile machines for their ability to cater to small-batch production and quick turnovers. This shift is primarily influenced by the rise of fast fashion and custom textile needs, pushing manufacturers to adapt to ever-changing consumer preferences.

Keeping pace with technological advancements, these machines incorporate automation and smart technologies, enabling a higher degree of precision and reduced labor costs.

In addition to market shifts, the demand for mini textile machines has been bolstered by the sustainable fashion movement. With consumers becoming more environmentally conscious, there’s a growing need for equipment that can support eco-friendly practices, such as low-water usage and reduced energy consumption. As a result, global buyers are seeking machines that not only meet their production needs but also align with sustainable goals. The trend indicates a robust future for mini textile machines, as manufacturers innovate to meet the evolving landscape of textile production.