Leave Your Message

The textile industry is undergoing a significant transformation, driven by the need for efficiency, sustainability, and innovation. Among the emerging technologies, the Water Jet Machine Textile stands out as a revolutionary tool, offering unparalleled precision and versatility in fabric cutting and processing. According to a report by Market Research Future, the global water jet cutting machine market is projected to reach USD 1.6 billion by 2023, with a significant portion attributed to its applications in the textile sector. This innovative machinery not only reduces material waste but also enables intricate designs with minimal downtime, thereby enhancing production workflows. As the demand for high-quality textile products continues to grow, the integration of water jet machines is proving to be a game changer, setting new standards in productivity and creativity within the industry.

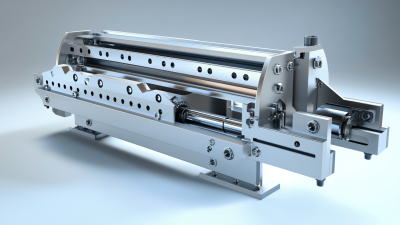

Water jet technology is revolutionizing textile fabric cutting, offering unprecedented precision and efficiency. Unlike traditional cutting methods that can fray edges or create inaccuracies, water jet machines utilize high-pressure water streams to slice through various materials with remarkable accuracy. This technology minimizes fabric waste, making it a cost-effective solution for manufacturers aiming to optimize resources.

In addition to its precision, water jet cutting is also environmentally friendly. It requires significantly less water than conventional methods and reduces the need for harmful chemicals often involved in cutting processes. The automated capabilities of water jet machines further enhance productivity, integrating seamlessly into the increasingly automated landscape of garment production. As the textile industry embraces cutting-edge technologies, water jet systems stand out for their ability to deliver clean cuts while supporting sustainable practices. With continuous advancements, this innovative technology is setting new benchmarks for fabric cutting in the textile sector.

Water jet machines are revolutionizing the textile industry by enabling advanced cutting techniques that enhance precision and efficiency. Key features of these machines include high pressure capabilities, which typically range from 30,000 to 90,000 PSI, allowing for the clean cutting of a wide variety of materials, including delicate fabrics that traditional cutting methods might damage. According to a report by MarketsandMarkets, the global water jet cutting equipment market is projected to reach $619 million by 2025, reflecting a significant increase in demand within the textile sector.

Water jet machines are revolutionizing the textile industry by enabling advanced cutting techniques that enhance precision and efficiency. Key features of these machines include high pressure capabilities, which typically range from 30,000 to 90,000 PSI, allowing for the clean cutting of a wide variety of materials, including delicate fabrics that traditional cutting methods might damage. According to a report by MarketsandMarkets, the global water jet cutting equipment market is projected to reach $619 million by 2025, reflecting a significant increase in demand within the textile sector.

Another notable aspect of water jet machines is their versatility. They can effortlessly handle multiple layers of fabric, cutting through materials like silk, denim, and even leather without fraying edges. This capability directly aligns with industry trends; the demand for intricate designs and eco-friendly processes has risen, contributing to a projected growth rate of 6.4% in the textile machinery market from 2020 to 2025. Furthermore, water jet cutting is a remarkably sustainable choice, minimizing waste and reducing energy consumption compared to conventional methods, which is increasingly important to environmentally conscious manufacturers.

The textile industry is undergoing a significant transformation as environmental sustainability becomes a critical focus. Water jet cutting machines stand out as a revolutionary alternative to traditional cutting methods, offering a myriad of benefits. According to a report by MarketsandMarkets, the global water jet cutting market is expected to reach $1.4 billion by 2025, demonstrating the growing acceptance and demand for this technology. Unlike traditional fabric cutting methods that often generate excess waste and require chemical treatments, water jet machines utilize high-pressure water streams, significantly reducing material waste by up to 50% while also eliminating the need for harmful chemicals.

In addition to cutting efficiency, the use of water jets aids in conserving energy. A study by the National Institute of Standards and Technology indicates that water jet cutting consumes up to 60% less energy compared to other cutting techniques, making it not only environmentally friendly but also cost-effective in the long run. Furthermore, water jet technology allows for intricate designs and precise cuts without fraying the fabric edges, minimizing the need for additional finishing processes that can further contribute to environmental degradation. As the textile industry continues to prioritize sustainability, water jet cutting machines will play an essential role in shaping a greener future for fabric production.

| Aspect | Water Jet Cutting | Traditional Cutting Methods |

|---|---|---|

| Material Versatility | High (can cut various materials) | Moderate (limited to specific materials) |

| Waste Generation | Low (minimal waste) | High (more offcuts and scraps) |

| Energy Consumption | Moderate | Higher |

| Cut Quality | Excellent (fine edges, no fraying) | Variable (depends on technique) |

| Environmental Impact | Lower (uses water, reduces pollutants) | Higher (emission of fumes and dust) |

| Setup Time | Quick (less preparation needed) | Longer (more setup needed) |

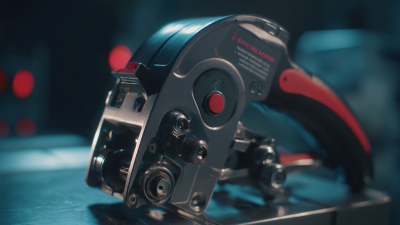

Water jet machines have revolutionized the textile design process, introducing innovative techniques that enhance creativity and efficiency. These machines utilize high-pressure water streams to cut and shape intricate designs on various fabrics, offering designers unprecedented precision. The ability to create complex patterns without the need for dyes or harmful chemicals makes water jet cutting a sustainable choice for the textile industry. As designers experiment with diverse textures and layers, they can visualize a broad spectrum of possibilities, allowing for more ambitious and avant-garde creations.

Moreover, water jet machines are not limited to traditional materials; they can cut through a wide range of textiles, including natural fibers, synthetics, and even composite materials. This versatility opens new avenues for experimentation in textile design, enabling designers to merge different materials into cohesive, eye-catching works. By combining fabrics in innovative ways, designers can play with color, texture, and structure, leading to a new era of artistic expression in textiles. As the technology continues to evolve, it promises to further push the boundaries of what is possible in textile design, making it an exciting time for designers in the industry.

The textile industry has increasingly adopted water jet technology for its precision and versatility, yet challenges remain in its widespread implementation. According to the International Journal of Advanced Manufacturing Technology, nearly 35% of textile manufacturers face difficulties with equipment integration while transitioning to water jet machines. These challenges often stem from the high initial investment costs and the requirement for specialized training for personnel. Additionally, many companies struggle to adapt their production processes to fully leverage the unique capabilities of water jet cutting, which can handle a variety of fabrics with minimal distortion.

To address these challenges, stakeholders in the textile sector are increasingly focusing on innovative solutions. For instance, strategic partnerships between equipment manufacturers and textile companies have shown to significantly reduce implementation time and costs. A report by Textiles Intelligence highlights that 60% of successful integrators utilized training programs focused on water jet technology, leading to a 40% increase in operational efficiency. Furthermore, advancements in software and machine design are making it easier for companies to incorporate water jet systems, enabling them to maintain a competitive edge in a rapidly evolving market. As the industry continues to explore the potential of water jet machines, overcoming these challenges will be key to unlocking enhanced productivity and creativity in textile manufacturing.