Leave Your Message

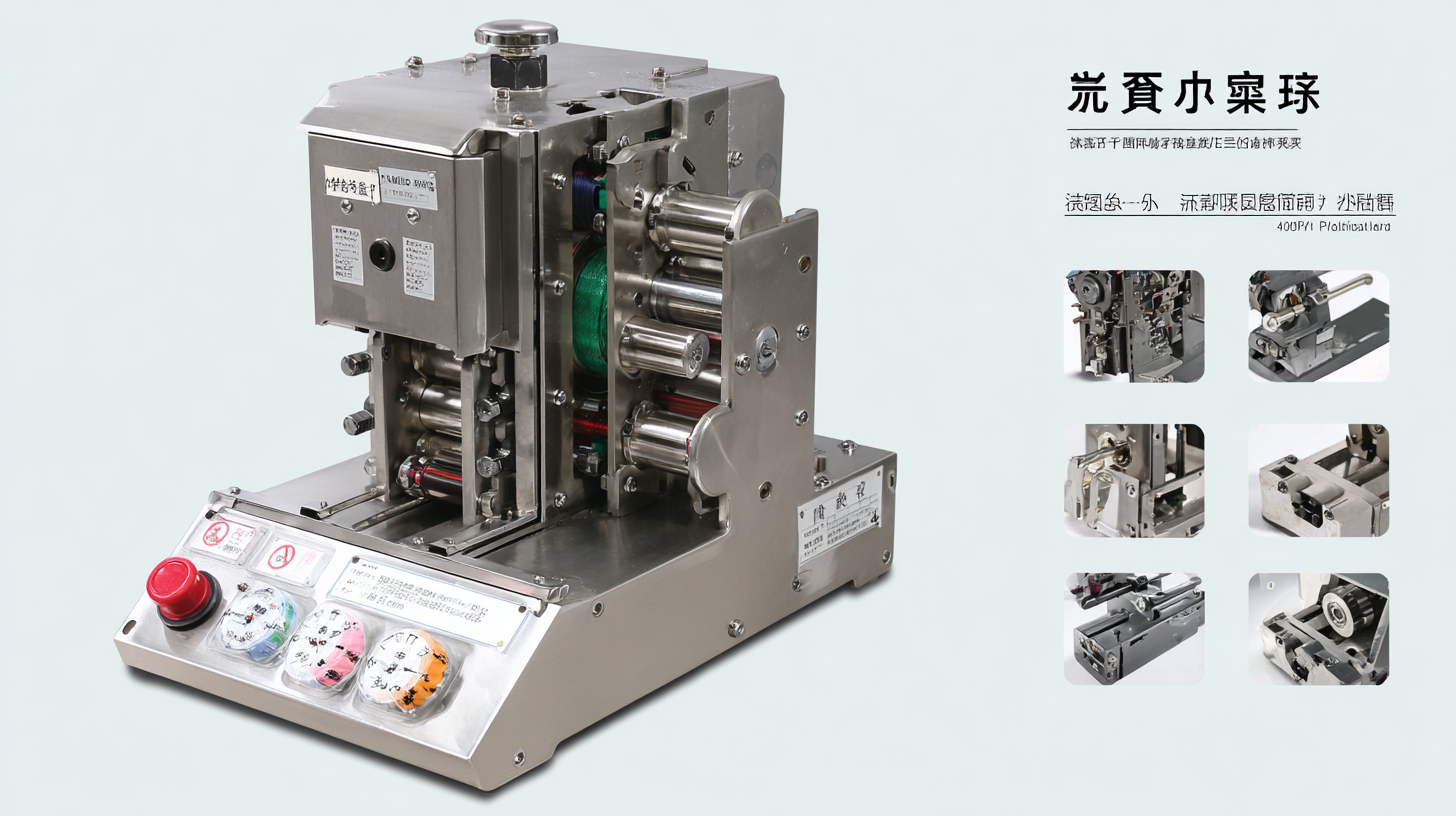

In the realm of manufacturing, the rise of China as a powerhouse is underscored by its advancements in producing world-class equipment, particularly the Professional Crimping Machine. According to a recent industry report by MarketsandMarkets, the global crimping machine market is projected to reach USD 1.4 billion by 2025, driven by the increased demand for precision in various sectors including automotive, electronics, and aerospace. China's commitment to innovation and quality has positioned it as a leader in this space, showcasing products that meet international standards and cater to a diverse clientele. The incorporation of smart technology into manufacturing processes has further enhanced the efficacy and reliability of Professional Crimping Machines, making them integral to enhancing operational efficiencies worldwide. As global export dynamics shift, China's pride in its manufacturing capabilities shines brightly, reflecting a future where quality and performance remain paramount.

China's journey towards world-class manufacturing excellence is a testament to the nation's commitment to innovation and quality. As highlighted in recent reports, China has made significant strides in transforming its manufacturing sector, now showcasing advanced capabilities that rival global standards. With the emergence of Global Capability Centres around the world, particularly in Asia, manufacturers are recognizing the strategic importance of innovation in maintaining competitiveness. Reports indicate that firms embracing new technologies and methodologies have increased efficiency and productivity, reflecting a broader industry trend.

Tip: Companies aiming to enhance their manufacturing processes should invest in digital transformations. This shift not only streamlines operations but also fosters a culture of continuous improvement. By leveraging data analytics and automation, businesses can identify bottlenecks and optimize production lines effectively.

Moreover, the transformative landscape of manufacturing is being shaped by a collaborative approach between industry leaders and academic institutions. China's burgeoning innovation ecosystem—bolstered by research and development initiatives—has positioned it as a frontrunner in advanced industries. The country’s universities and enterprises are contributing to a robust talent pipeline, ensuring that the workforce is equipped with the necessary skills to drive future advancements.

Tip: To capitalize on this talent, businesses should prioritize partnerships with educational institutions, creating internship and training programs that align with industry needs. This not only enhances workforce readiness but also fosters innovation through fresh perspectives.

In the rapidly evolving landscape of manufacturing, innovative technologies in crimping machines are significantly elevating industry standards. According to a recent report by the Global Crimping Machine Market Analysis, the crimping machinery market is projected to reach USD 1.2 billion by 2025, driven by the demand for precision and efficiency in various sectors, including automotive, aerospace, and electronics. The advent of advanced automation and AI-driven functionalities in crimping machines has not only enhanced production rates but also improved accuracy, minimizing waste and operational costs.

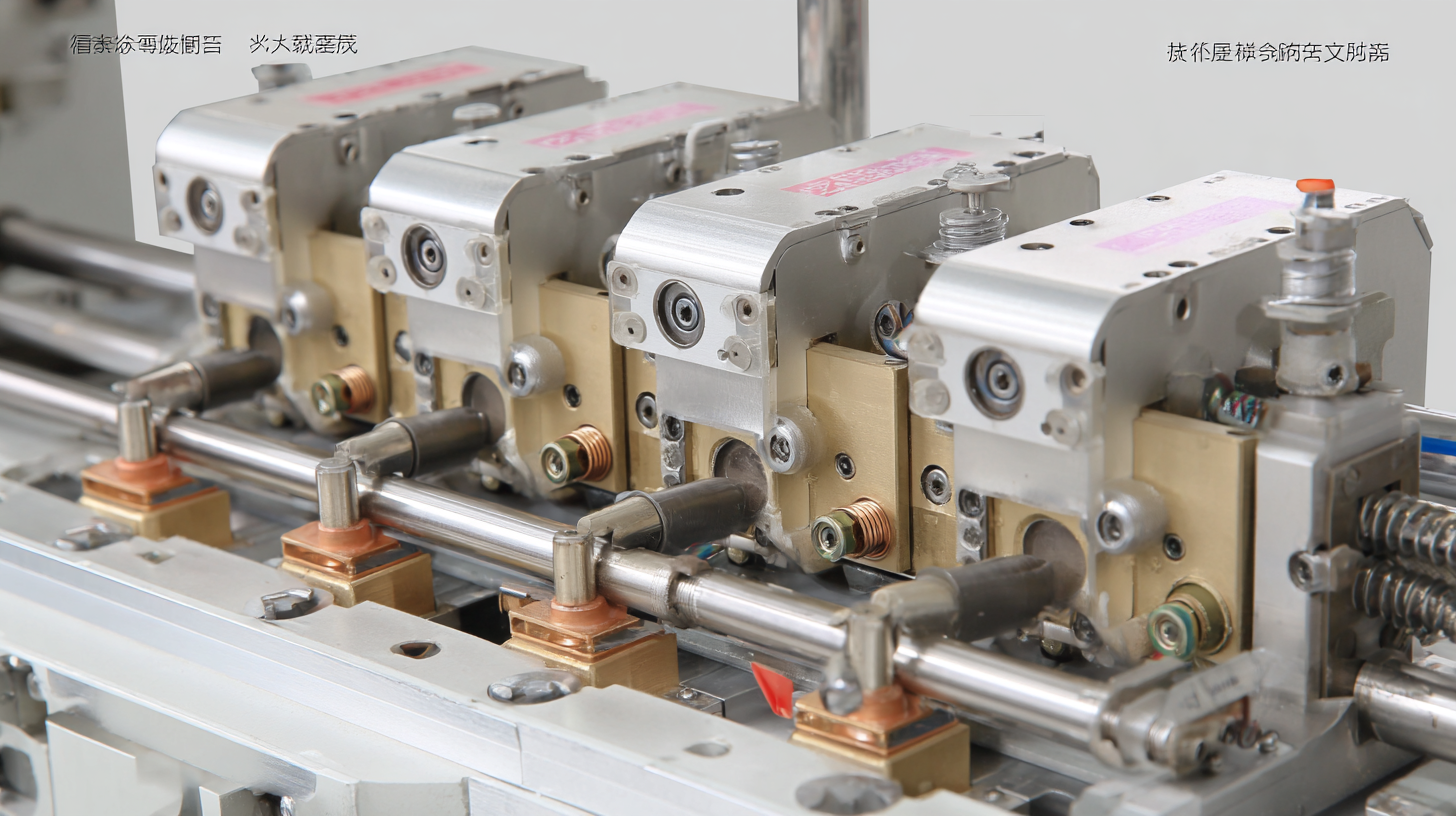

Furthermore, advancements in material science have led to the development of specialized crimping tools that ensure better durability and performance. A study conducted by the International Journal of Manufacturing Technology highlights that machines incorporating smart technology can reduce downtime by up to 30% and increase throughput by 25%. These innovative approaches are allowing manufacturers to maintain a competitive edge in a global market characterized by stringent quality standards and increasing consumer expectations. China's commitment to adopting and showcasing such world-class manufacturing practices positions the nation as a leader in producing high-quality crimping machines for global export.

In the fiercely competitive landscape of global manufacturing, quality control practices play a crucial role in ensuring that products meet international standards. The implementation of stringent quality assurance measures is vital for manufacturers like those in China, especially when it comes to producing best-in-class crimping machines for export. By adopting advanced quality control methodologies, manufacturers can systematically monitor and improve their processes, identifying potential flaws before they reach the market.

One effective approach is the integration of statistical process control (SPC), which allows manufacturers to analyze production data in real-time. This technique helps in maintaining consistency and reducing variability in product quality. Additionally, regular audits and compliance checks against international safety and performance standards ensure that every crimping machine produced not only meets but exceeds global expectations. This commitment to quality not only enhances brand reputation but also fosters trust among international partners and customers, positioning Chinese manufacturers as leaders in the global market.

China's manufacturing industry has long been recognized for its scale and efficiency, but an emerging focus on sustainability is redefining its global reputation. In the realm of crimping machines—essential tools for numerous industries—China is stepping up its commitment to environmental responsibility. Manufacturers are increasingly prioritizing eco-friendly materials and energy-efficient production processes, ensuring that their machines not only excel in functionality but also adhere to the principles of sustainability.

An integral part of this commitment is the adoption of innovative manufacturing practices. By integrating renewable energy sources and implementing waste reduction strategies, Chinese manufacturers are not only lowering their carbon footprint but also setting benchmarks for best practices globally. The shift towards sustainable production aligns with global trends, where consumers are progressively favoring products that are made with consideration for the environment. This evolution reflects a broader understanding that economic success and environmental stewardship can go hand in hand, showcasing China’s determination to lead in not just quantity, but quality and responsibility in the manufacturing sector.

| Aspect | Details |

|---|---|

| Manufacturing Type | Professional Crimping Machines |

| Production Volume (Units/Year) | 150,000 |

| Export Markets | North America, Europe, Asia |

| Sustainability Practices | Recycling Materials, Energy-Efficient Production Methods |

| Green Certifications | ISO 14001, RoHS Compliance |

| Carbon Emission Reduction Target | 25% by 2025 |

| Employee Training Programs | Sustainability Awareness, Safety Procedures |

The global manufacturing landscape is witnessing a significant evolution, with Chinese crimping machines taking center stage. As industries worldwide seek efficiency and reliability, the demand for high-quality crimping solutions is on the rise. This new wave of interest offers a promising opportunity for Chinese manufacturers to capitalize on the trends shaping the future of global exports. The adaptability and innovation demonstrated by these manufacturers are setting a precedent, making them key players in the international market.

The global manufacturing landscape is witnessing a significant evolution, with Chinese crimping machines taking center stage. As industries worldwide seek efficiency and reliability, the demand for high-quality crimping solutions is on the rise. This new wave of interest offers a promising opportunity for Chinese manufacturers to capitalize on the trends shaping the future of global exports. The adaptability and innovation demonstrated by these manufacturers are setting a precedent, making them key players in the international market.

Moreover, the continuous improvements in technology and production processes have enabled Chinese crimping machines to meet the stringent quality standards required by various industries. As countries around the globe look to enhance their production capabilities, the focus on sourcing advanced machinery from China becomes increasingly appealing. This signifies not only a shift in export patterns but also highlights China's growing reputation as a hub for world-class manufacturing.

Furthermore, the integration of smart technologies into crimping machines presents an exciting opportunity for further growth. Manufacturers are actively investing in research and development to create machines that offer enhanced functionality and efficiency. This trend not only enables Chinese companies to stay competitive but also positions them as innovators in the global manufacturing arena, paving the way for sustainable export growth.